What is the Jorlon Diaphragm?

All Steriflow Valves with a Jorlon diaphragm have a lifetime warranty on the diaphragm.

Before we look at the Jordan diaphragm, it is important to understand what a diaphragm is. A diaphragm is a flexible membrane that moves in response to pressure changes and helps regulate flow in valves, pumps, and regulators.

Jorlon Diaphragm – a Lifelong Performer

Jorlon has been used by Steriflow for over 15 years, with tens of thousands of Steriflow valves with Jorlon™ Diaphragm installed in FDA-approved systems and facilities.

To date, not one valve has been returned due to diaphragm failure when operating within its use parameters.

Jorlon has been nitrogen pressure tested to over 1200 psi without failure.

Jorlon Diaphragm Facts

- FDA compliant

- USP certified

- ADI/TSE free

- Incredibly dependable

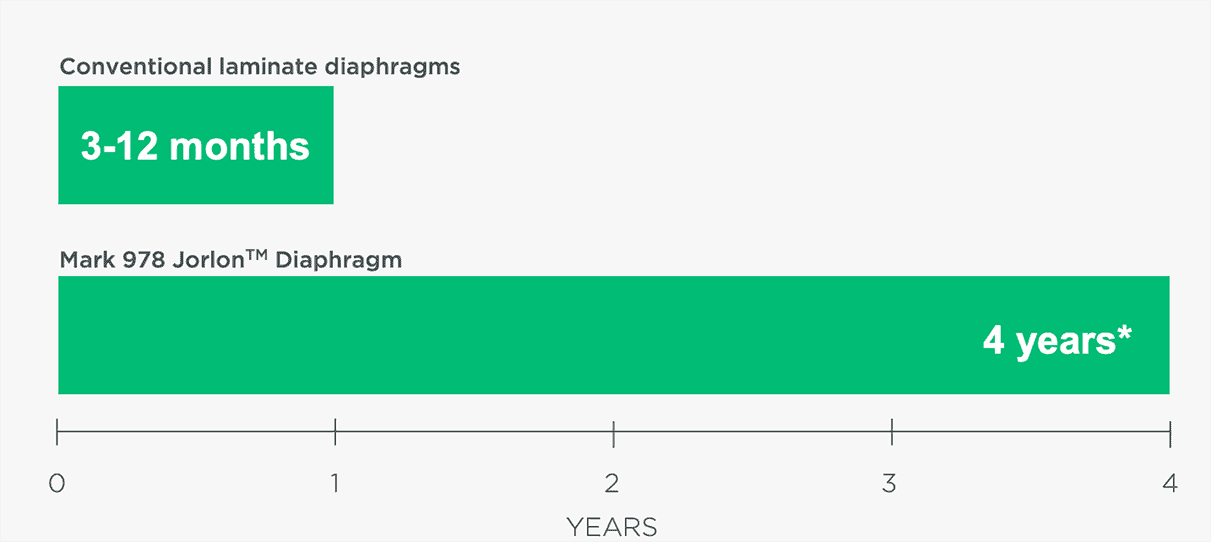

- Long lasting (years longer than laminated diaphragms)

How It’s Made

Our Jorlon diaphragms are structurally modified with pure PTFE. The diaphragm is manufactured by a proprietary technique where PTFE layers are combined and formed in a unique process to reduce the creep and cold flow associated with conventionally formed solid or laminated PTFE or Teflon.

The product is thoroughly tested for durability, making sure you get the best results possible. Jorlon™ is warranted for a lifetime of use on:

Benefits of the Jorlon Diaphragm

With a Jorlon Diaphragm you can:

- Save money

- Extend preventive maintenance diaphragm change-out times

- Realize the benefits of a regulator and control valve that outlasts most normal systems

Product Applications

Jorlon has been specified in biopharm applications including:

| WFI | Cryogenic liquids |

| Clean steam (up to 100 psig) | Clean compressed air and gas |

| CIP fluid | Biological intermediates |

| Buffers | Final process fluids |

| Acids | — |

What Are the Advantages of Valves With a Jorlon™ Diaphragm?

Aseptic and reliable valve components are extremely important in the pharmaceutical industry. Since they see the most wear, automated control valve and regulator valve diaphragms are particularly vital. Without a reliable diaphragm, the dependability of your aseptic process could be in serious jeopardy.

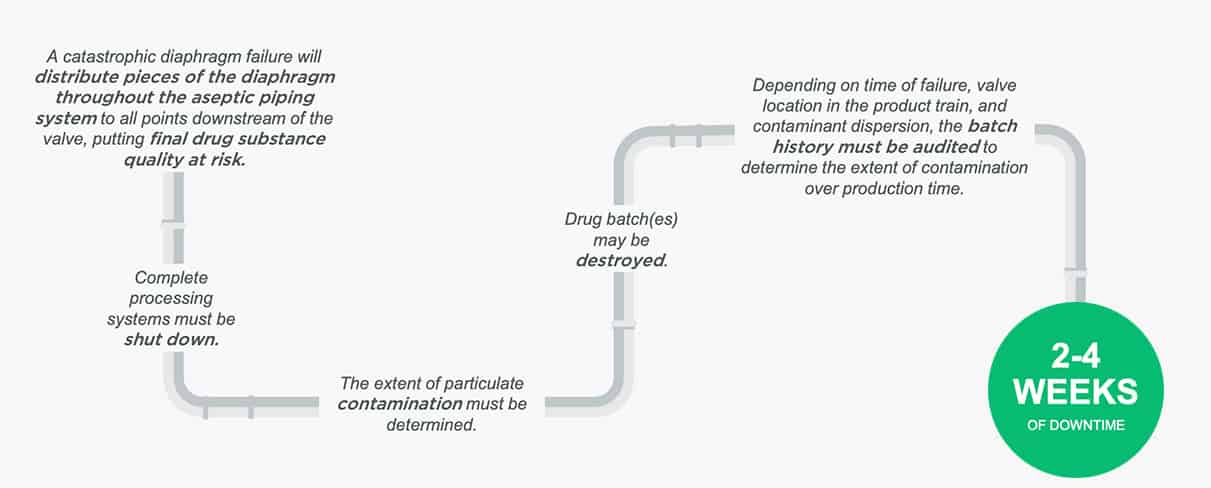

How Costly is a Diaphragm Failure?

Unscheduled shutdowns can result in 2 weeks to a month of downtime — no production!

- A catastrophic diaphragm failure will distribute pieces of the diaphragm throughout the aseptic piping system to all points downstream of the valve, putting final drug substance quality at risk.

- Complete processing systems must be shut down.

- The extent of particulate contamination must be determined.

- Drug batch(es) may have to be destroyed.

- Depending on time of failure, valve location in the product train, and contaminant dispersion, the batch history must be audited to determine the extent of contamination over production time.

How Can I Prevent a Diaphragm Failure?

Prevent diaphragm failure with a Jorlon diaphragm. Jorlon™ is a structurally modified, non-laminated, pure PTFE diaphragm material that provides a sterile barrier between the process and outside environment, and increases the life of your control valves and regulators.

Jorlon has been successfully tested on a variety of Steriflow valves:

- Cyclic Testing: Successfully tested on a variety of Steriflow valves on 45 psig (3 bar) continuous steam service to over 1 million full stroke cycles Jorlon™ has successfully tested nitrogen pressure to over 1,200psi

- Lab Testing: The valves were successfully tested with an additional 100 steam and vacuum styles. Lab tests comparing JorlonTM to 316L diaphragms show continued life after exceeding the SST failure cycle count by more than 100 times.

Jorlon™ Diaphragm Maintenance

Jorlon™ reduces the need for excessive preventive maintenance. A customer with a 200+ regulator population reported a maintenance 9-year period without a single regulator maintenance event.

What is the Shelf Life?

Jorlon™ diaphragm has an indefinite shelf life based on ideal storage conditions:

- Store flat in a cool, dry area.

- Do not fold or bend.

- If exposed to greases, oils, or solvents in liquid or vapor form, clean thoroughly before installing.

- Store away from incidental exposure to all types of radiation.

- Following extended storage, carefully inspect the material for damage.

If in doubt concerning any of the above provisions, contact our team.

Jorlon™ Diaphragm Warranty

Steriflow, a division of Jordan Valve, warrants the Jorlon diaphragm for use on all of its control valves and gas regulators as defined:

- J-Series Gas Regulators: Models JSRLF, LSRLFLP, JSR, JSRLP, JSRH, JSRHF, JSB

- Mark 96 and Mark 95 manual and air loaded clean utility and process PRVs and BPRVs

- Mark 978 Series control valves and JSHM manual control/metering valves

All are warranted for a lifetime of use on all Clean Utility, WFI and gas applications at the operating pressure, temperatures and conditions as specified in each model’s data sheet. Download our Jorlon Diaphragm Warranty PDF for more details.

Mark 96 Series Sanitary Pressure Regulators

Mark 96 Series Sanitary Pressure Regulators  JSR Series Compressed Air & Gas Regulators

JSR Series Compressed Air & Gas Regulators