Clean Steam Valves

Clean steam valves are designed for controlling the flow, pressure, and distribution of clean steam in sanitary applications.

Our valves are built to meet strict hygiene and sterility requirements, ensuring contaminant-free operation in industries such as pharmaceuticals, biotechnology, food processing, and healthcare.

Our clean or pure steam valves are designed to ensure hygienic operation, high-temperature and corrosion resistance, compliance with FDA, USP, ASME BPE, and 3-A standards, and minimal dead space to prevent contamination and support efficient sterilization.

Our Range of Sanitary Valves for Clean Steam

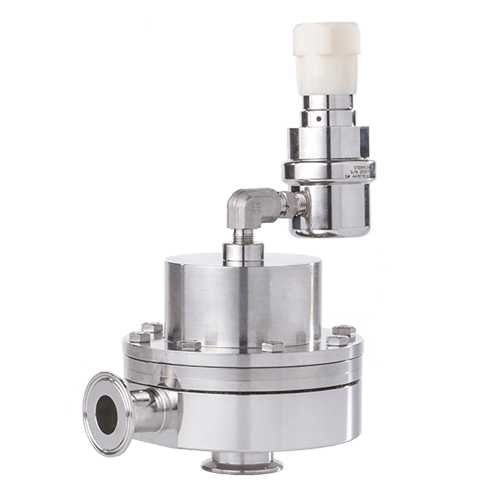

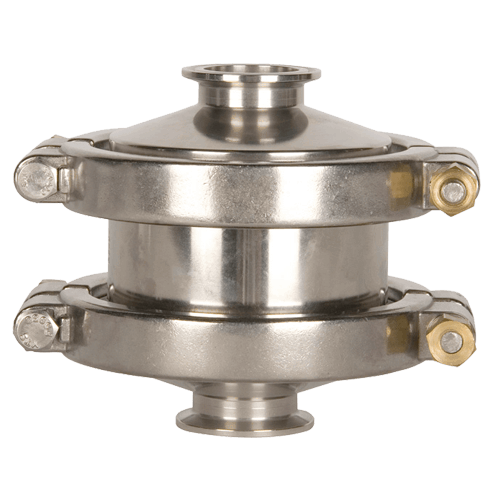

Sanitary Safety Relief Valve ⟶

ASME Section VIII compliant, CE/UKCA Certified

Made in the USA

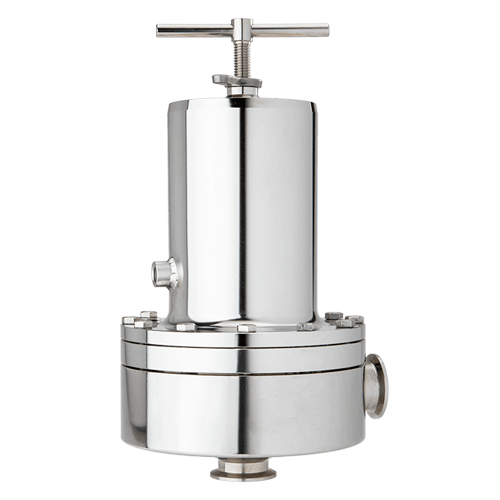

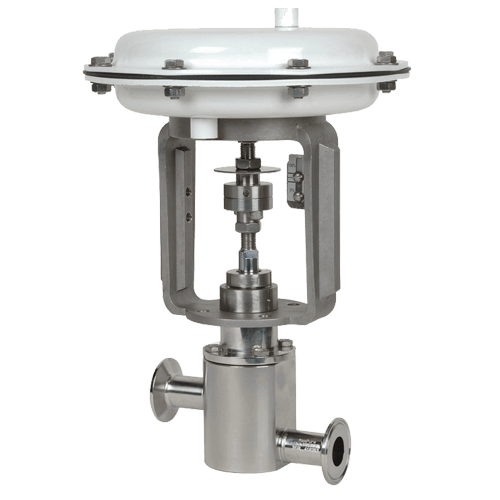

Mark 96 Series ⟶

Manual, Low to High Flow, Sanitary Pressure Regulator

Mark 96C Series ⟶

Manual, Low to High Flow, Jorlon Diapragm

Mark 96A Series ⟶

Hybrid or Automated, Jorlon Diaphragm

Mark 96AA Series ⟶

Hybrid or Automated, Jorlon Diaphragm

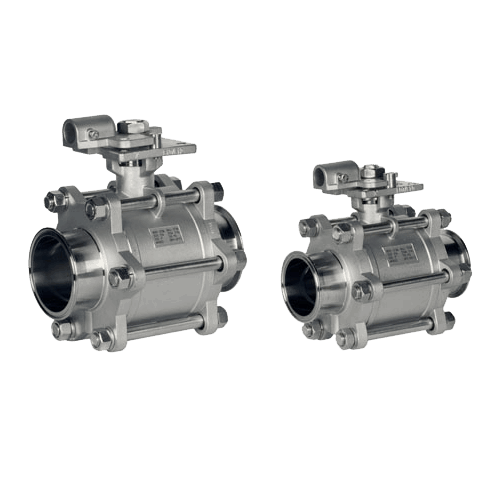

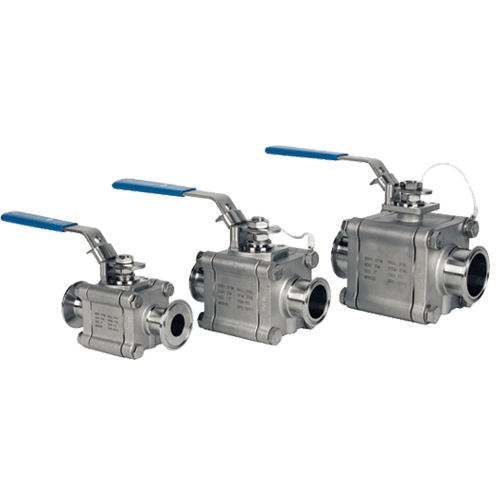

Mark 9020 BPE Series ⟶

2-Way Sanitary Ball Valves

Mark 9020D DIN Series ⟶

2-Way Sanitary Ball Valves

Mark 9020S ISO Series ⟶

2-Way Sanitary Ball Valves

Mark 978JD Series ⟶

Medium to high flow, Jorlon diaphragm

Mark 978M Series ⟶

Manual control, low to high flow, Jorlon diaphragm

JSHM Series ⟶

Manual control, low to medium flow, Jorlon diaphragm

Mark 978INLINE Series ⟶

Medium to High Flow, Jorlon Diaphragm

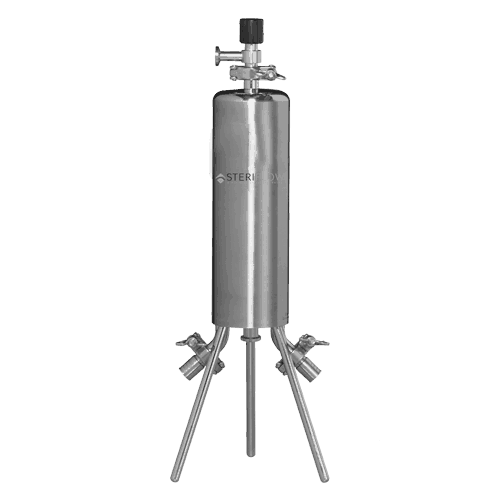

SC60 Series ⟶

Permanent and Portable Installation

SC50 Series ⟶

Permanent and Portable Installation

SC30 Series ⟶

Sample Coolers

Mark 93 Series ⟶

Medium to high flow, <3°F (1.7°C) subcool operation

Mark 93JR Series ⟶

Compact, Low to Medium Flow, <3°F (1.7°C) Subcool Operation

Mark 93TH Series ⟶

Threaded, compact, low to medium flow <3°F (1.7°C) subcool operation

Mark 934 Series ⟶

High - ultra flow, <3°F (1.7°C) subcool operation

Mark 94 Series ⟶

High flow, <3°F (1.7C °C) subcool operation

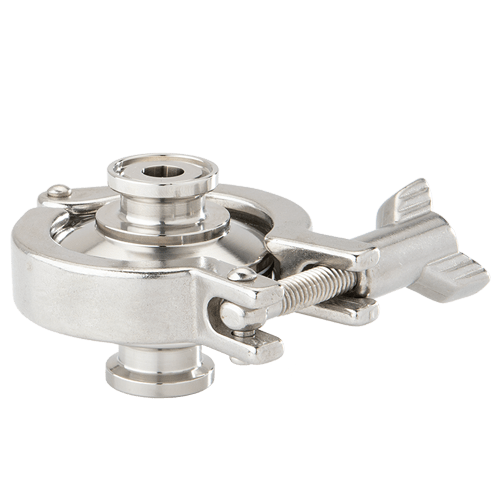

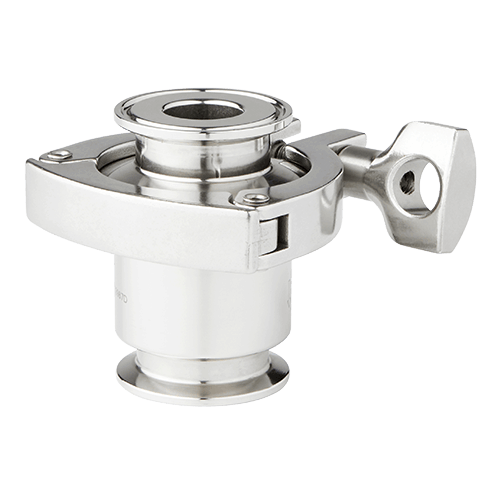

SV Series ⟶

The Sample Valve is specifically designed to precisely control the flow of fresh clean steam or hot WFI into a sample cooler

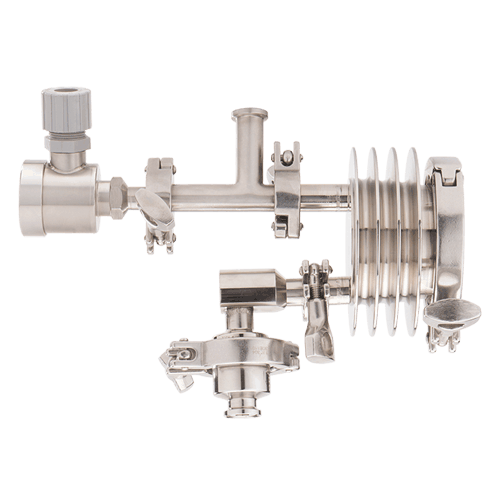

SSC Series ⟶

For compact, validated SIP sensor/steam trap drain installations