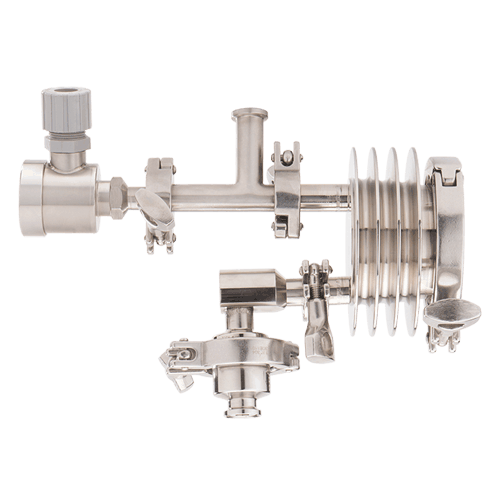

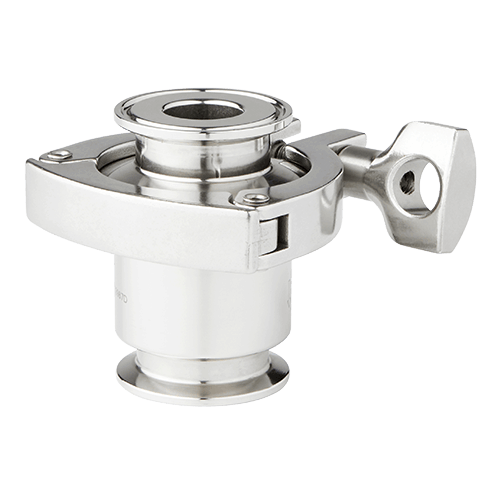

SSC Series

For compact, validated SIP sensor/steam trap drain installations

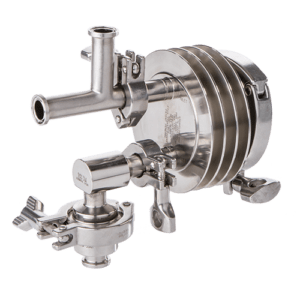

Compact, drainable, sanitary condensate chamber and steam trap assembly designed to replace or reduce the 12 - 18" (300 - 450mm) c-c dimension between traditional steam trap and validation sensors. Designed to reduce the time required for heat-up (improves drainage), and prevent condensate back-up during temperature maintenance (validation alarms).

- Upstream and downstream process vessels

- To accelerate heat-up and eliminate validation temperature alarms

- To allow installation of validated SIP drain line/traps where space is limited

- Mobile or stationary formulation vessel: to expedite SIP heat-up by installation on fixed, validated drain lines

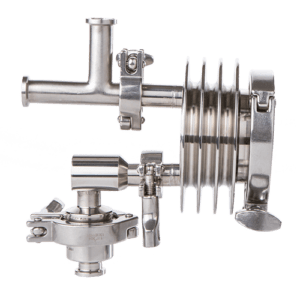

- Increases process availability by:

- decreasing SIP heat-up time

- lowering the probability of SIP validation temperature alarms

- Increases drainage by cooling condensate before entering trap enabling the bellows to contract opening orifice

- Can reduce CAPex if assembly is purchased per-assembled compared with site fabricated installation

- Reduces the lineal space required for a validated SIP steam trap downcomber assembly by 80%

- Connection Size/Type: 3/4″ ASME BPE Tri-clamp end connections standard

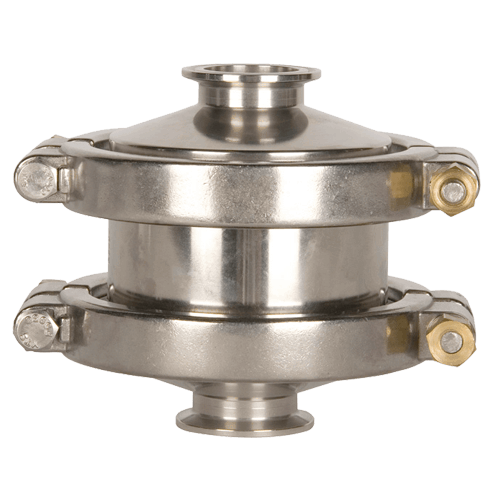

- Maximum Operating Pressure: 145 psig (10 barg); Note: drain system maximum operating is determined by attached steam trap

- Materials of construction: ASME SA479 316L (UNS 31603) is standard. EN 10272:2000 GR 1.4435, AL-6XN®, Hastelloy C-22 and others are optional

- Capacity: Capacity dependent on trap attached to outlet. Unit cools condensate before steam trap enabling the bellows to contract, opening orifice further

- Surface Finish: Internal: SF1, 20 Ra μin (0,5 μm) standard; SF5, 20 Ra μin (0,5 μm) electropolish optional

- Radiant and Convective Heat Loss: Cools entering condensate by an average 30°F at ambient temperatures

An Overview of Steam-In-Place

A comprehensive overview of SIP, existing components, piping design, and the new technology used to reduce common problem occurrences.

Steam Trap Comparison Chart

Understanding the differences among the full line of Steriflow steam traps

- CRN (Canadian Registration Number)

- All products use FDA and USP Class VI approved soft goods and seals where possible. Consult each product data for details

Your List

Email List

Get A Quote

Related Products

Mark 93 Series

Medium to high flow, <3°F (1.7°C) subcool operation

Mark 934 Series

High - ultra flow, <3°F (1.7°C) subcool operation

Mark 94 Series

High flow, <3°F (1.7C °C) subcool operation

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.