Pressure Control (Buffer)

Mark 95 Series ⟶

Manual, Low to High Flow, Sanitary Back Pressure Regulator

Mark 95A Series ⟶

Fully Automated, Low to High Flow, Normally Open, Jorlon Diaphragm

Mark 95AA Series ⟶

Hybrid or Automated, Low to High Flow, Jorlon Diaphragm

Mark 95FT Series ⟶

Manual, Flow-Through Body, Low to High Flow, Jorlon Diaphragm

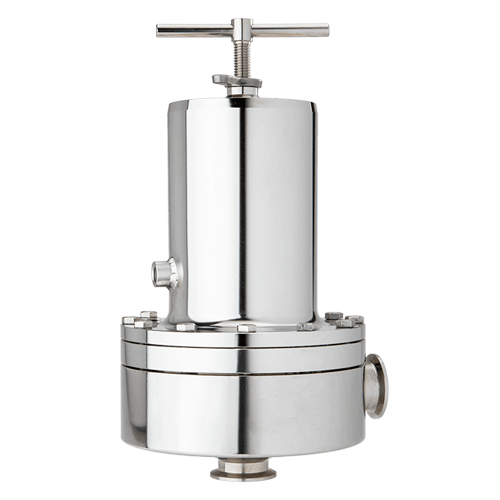

Mark 96 Series ⟶

Manual, Low to High Flow, Sanitary Pressure Regulator | Quick Ship Available

Mark 96C Series ⟶

Manual, Low to High Flow, Jorlon Diapragm | Quick Ship Available

Mark 96A Series ⟶

Hybrid or Automated, Jorlon Diaphragm

Mark 96AA Series ⟶

Hybrid or Automated, Jorlon Diaphragm | Quick Ship Available

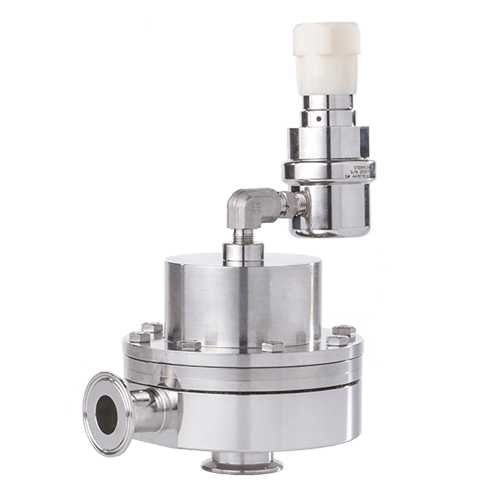

JSB Series ⟶

Manual Or Air Loaded, Low To Medium Flow, Sanitary Back Pressure Regulator

Size ranges: 1/2" & 3/4"; Cv's: 0.8, Cv for relief valve sizing: 1.9; 0.5, Cv for relief valve sizing is 0.6

Spring range: 8-40 psi; 35-60 psi; 50-125 psi

Mark 978JD Series ⟶

Medium to high flow, Jorlon diaphragm

Mark 978M Series ⟶

Manual control, low to high flow, Jorlon diaphragm

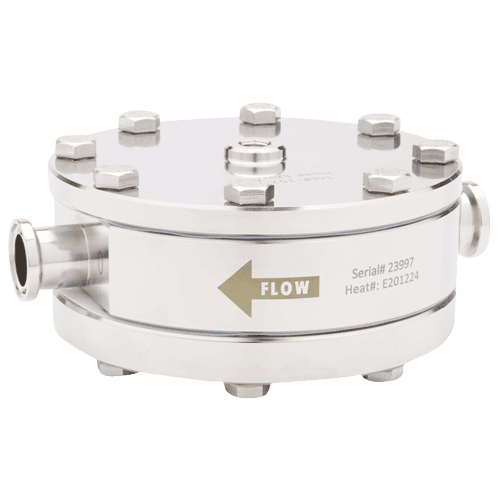

Mark 978INLINE Series ⟶

Medium to High Flow, Jorlon Diaphragm

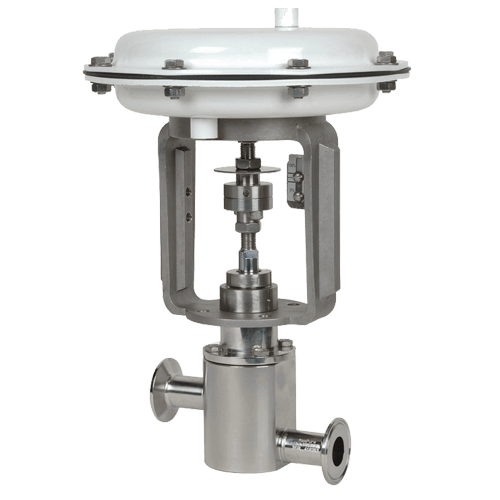

FD Series – BPRV ⟶

Excellent Stability Over A Wide Flow Range; Smooth Computer Automation;

Precision Pressure or Automated Flow Control

Your List

Email List

Get A Quote

In sanitary systems, keeping pressure stable is essential for smooth operation, protecting equipment, and maintaining product quality. A Pressure Control Buffer absorbs pressure changes, reduces surges, and ensures steady flow to downstream equipment. By using sanitary pressure regulator valves and sanitary pressure control valves, industries can achieve accurate fluid pressure control, reduce equipment stress, and maintain efficient operations.

The Pressure Control Buffer is widely used in pharmaceutical, biopharma, and food & beverage operations, providing reliable performance in critical processes.

What Is Pressure Control Buffer?

A Pressure Control Buffer is a process that maintains stable pressure within a buffer volume, serving as an intermediary between a supply source and downstream equipment.

- Pressure sensors continuously monitor the system.

- Pressure regulator valves adjust flow to maintain a precise setpoint.

- The Pressure Control Buffer absorbs surges and prevents drops that could affect downstream equipment.

- Sanitary pressure control valves ensure hygienic operation while delivering precise fluid pressure control.

By combining a buffer volume with high-quality valves, the Pressure Control Buffer maintains operational consistency, safety, and reliability.

Why Pressure Control Buffer Is Important

- Provides smooth and reliable fluid pressure control in critical operations

- Absorbs pressure fluctuations to protect sensitive equipment

- Ensures continuous flow for point-of-use applications

- Uses pressure regulator valves to maintain precise pressure levels

- Maintains hygienic standards through sanitary pressure control valves

The Pressure Control Buffer is essential for processes where pressure stability directly impacts product quality, equipment reliability, and operational efficiency.

Where Pressure Control Buffer Is Used

The Pressure Control Buffer process is applied in systems that require stable and predictable pressure:

- Purified water and buffer solution distribution systems

- Clean steam networks and utility lines

- Chromatography columns and filtration operations

- Compressed air systems requiring precise fluid pressure control

In all these applications, the pressure buffer absorbs transient pressure fluctuations while sanitary pressure regulator valves and sanitary pressure control valves maintain consistent performance.

Industries Using Pressure Control Buffer

The Pressure Control Buffer is vital across multiple industries:

- Biopharmaceutical and pharmaceutical manufacturing

- Food and beverage processing

- Laboratories and research facilities

These industries rely on Pressure Control Buffer systems with sanitary pressure regulator valves and sanitary pressure control valves to maintain operational stability, safety, and high-quality output.

Applications

- Chromatography column outlet Pressure Control Buffer

- Purified water or buffer solution distribution

- Point-of-use buffer regulation in critical processes

- Sanitary and high-purity operations in biopharma, pharmaceutical, and food industries

By using sanitary pressure regulator valves and sanitary pressure control valves, industries can achieve consistent fluid pressure control, protect equipment, and maintain high-quality production.

Ready to Optimize Your Pressure Control (Buffer) Distribution?

Contact Steriflow Valve today to discuss how our Mark 978JD, 978M, and 978INLINE Series can enhance your Pressure Control (Buffer) Distribution System and Process Flow Control.