Chromatography Column Outlet Pressure Control

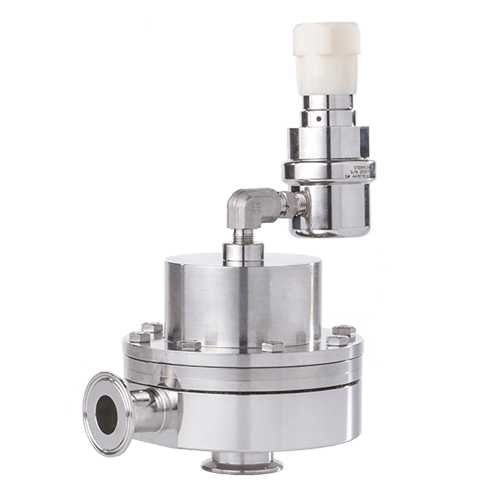

Mark 95 Series ⟶

Manual, Low to High Flow, Sanitary Back Pressure Regulator

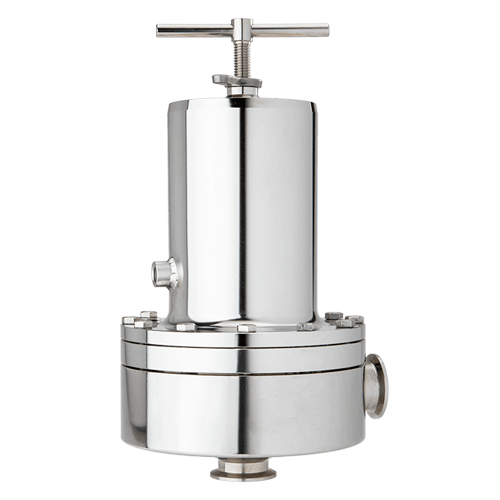

Mark 95A Series ⟶

Fully Automated, Low to High Flow, Normally Open, Jorlon Diaphragm

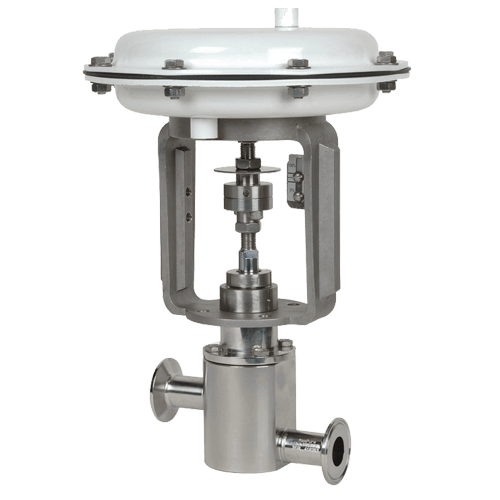

Mark 95AA Series ⟶

Hybrid or Automated, Low to High Flow, Jorlon Diaphragm

JSB Series ⟶

Manual Or Air Loaded, Low To Medium Flow, Sanitary Back Pressure Regulator

Size ranges: 1/2" & 3/4"; Cv's: 0.8, Cv for relief valve sizing: 1.9; 0.5, Cv for relief valve sizing is 0.6

Spring range: 8-40 psi; 35-60 psi; 50-125 psi

Mark 978JD Series ⟶

Medium to high flow, Jorlon diaphragm

Mark 978M Series ⟶

Manual control, low to high flow, Jorlon diaphragm

Mark 978INLINE Series ⟶

Medium to High Flow, Jorlon Diaphragm

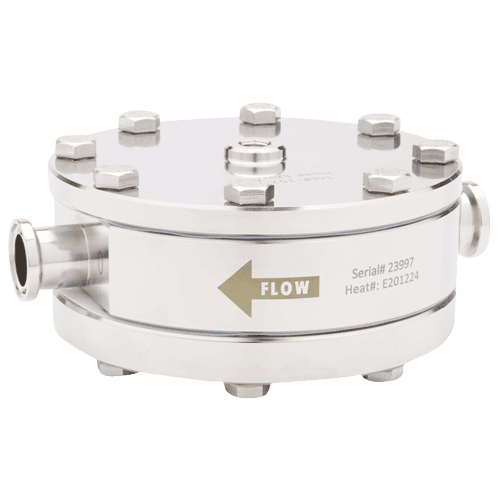

FD Series – BPRV ⟶

Excellent Stability Over A Wide Flow Range; Smooth Computer Automation;

Precision Pressure or Automated Flow Control

Your List

Email List

Get A Quote

Ensuring Precise Chromatography Column Outlet Pressure Control

Our chromatography column outlet pressure control ensures precise and stable regulation of buffer flow exiting chromatography columns. Proper outlet pressure is essential for achieving consistent separation and purification in both laboratory and industrial processes. Without effective control, chromatography columns can experience uneven flow, resin damage, or reduced separation efficiency, potentially affecting product quality.

Example: In protein purification for biopharmaceutical production, maintaining stable outlet pressure ensures that the target protein is separated efficiently from impurities, resulting in high-purity product with minimal waste.

By maintaining ideal outlet pressure, scientists, engineers, and lab managers can protect costly chromatography columns, improve reproducibility, and achieve consistent experimental results. This system integrates easily with standard chromatography setups, delivering reliable performance across both research and production applications.

How Chromatography Column Outlet Pressure Control Works

The principle behind chromatography column outlet pressure control is simple but highly effective. As the buffer solution flows through a chromatography column, the outlet pressure is carefully regulated to ensure that components in the mixture separate correctly.

-

Maintains steady flow:

Prevents uneven separation caused by fluctuating pressure.

-

Protects chromatography columns:

Avoids resin compaction, channeling, or mechanical damage.

-

Ensures consistent results:

High-quality, reproducible outcomes in protein purification, chemical separation, or pharmaceutical applications.

Example: In a biopharmaceutical lab, using an unregulated column can result in protein loss or contamination. With effective outlet pressure control, the buffer flows evenly, keeping proteins properly separated and protecting the column, reducing downtime and cost.

This control system works with chromatography columns of various scales, from lab research columns to high-throughput industrial columns, and allows precise adjustment to optimize separation performance.

Why Chromatography Column Outlet Pressure Control Matters

A chromatography column is the core of any separation process. Its efficiency depends heavily on stable flow and controlled pressure. Using an outlet pressure control system prevents:

- Resin channeling or uneven packing

- Poor separation of target molecules

- Overpressure that could damage the column

Steriflow Valves: Tools to Achieve Precise Outlet Pressure Control

Steriflow offers a variety of pressure control valves that implement reliable chromatography column outlet pressure control across different laboratory and industrial applications:

- Mark 95 Series: Provides precise outlet pressure control for lab-scale columns, ensuring stable buffer flow and consistent separation.

- Mark 95A Series: Reliable for medium-throughput chromatography columns, perfect for repeated protein purification and chemical separation.

- Mark 95AA Series: High-precision valves for advanced systems, delivering uniform flow and protecting sensitive resins.

- FD Series: Dependent buffer flow control for both research and production-scale chromatography columns, maintaining consistent results.

- JSB Series: High-accuracy pressure control valves for sensitive biochemical separations, minimizing column wear.

- Mark 978JD Series: Provides steady outlet pressure for large-scale industrial applications, protecting expensive columns.

- Mark 978M Series: Reliable valve solution for pilot or production-scale chromatography columns, optimizing separation efficiency and reducing downtime.

- Mark 978INLINE Series: Designed for high-throughput systems, ensures precise buffer flow and consistent yields across multiple batches.

Enhancing Chromatography Column Performance

The chromatography column outlet pressure control system is essential for anyone seeking reliable, precise, and efficient chromatography operations. By combining high-precision engineering with robust design:

- Expensive chromatography columns are protected

- Buffer flow remains consistent

- Separation efficiency and reproducibility are improved

- Operational costs and downtime are reduced

Whether for protein purification, chemical separation, or pharmaceutical production, Steriflow provides the control, safety, and performance your chromatography columns require.

Why Choose Chromatography Column Outlet Pressure Control

Implementing chromatography column outlet pressure control ensures:

- High-precision buffer flow regulation

- Protection of columns and sensitive resins

- Consistent, reproducible experimental and production results

- Easy integration with lab, pilot, or industrial chromatography setups

- Cost-efficiency through reduced downtime and column wear

By combining the control system with Steriflow’s range of pressure control valves, you can achieve optimal chromatography performance across applications of any scale.