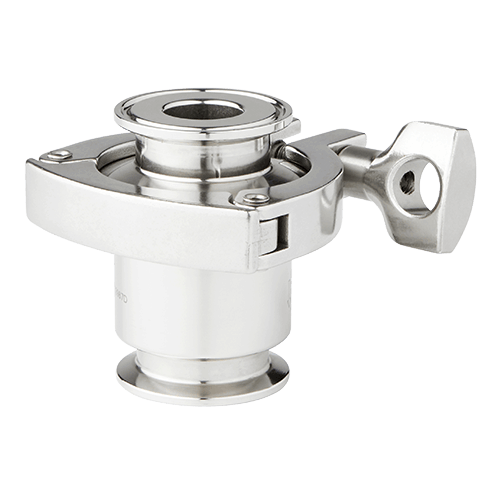

Mark 94 Series

High flow, <3°F (1.7C °C) subcool operation

Two piece tri-clamp body, balanced port, high flow thermostatic sanitary steam trap with vertical or horizontal inlet and/or outlet connections for pure steam SIP and loop drainage applications in biopharmaceutical and aseptic food & beverage and consumer health & beauty industry applications.

- Up and downstream process vessel medium sized vessel, validated SIP drainage applications

- Up and downstream process tubing: high flow validated SIP tubing drain applications

- Sterile filter, large vent and product filters validated SIP condensate drain applications

- Low subcooling operation reduces probability of SIP delays caused by temperature validation faults

- Easy thermal element (bellows assembly replacement only installs in one direction) error-proof

- New design provides excellent flow rates with low subcooling – improves heat-up drainage

- Self-draining when installed vertically (body outlet side down) – either vertical or horizontal connections

- Solid barstock body with fewer cracks and crevices than competitive designs

- Size: 3/4″, 1″, 1-1/2″ (DN20, DN25, DN40)

- Installation Connection Orientation: Vertical, Horizontal

- Connection Type: ASME, DIN, ISO Tri-Clamp and Tube Weld Ends

- Max. Allowable Pressure Temperature: 145 psig (10 barg); 350°F (177°C)

- Materials of Construction: Wetted body/plug material: ASME SA479 316L (UNS 31606) is standard. EN 10272:2000 GR 14435 is optional. Body gaskets: various, all FDA and USP Class VI

- Nominal Cv (Kv): 4.0 (3,45)

- Surface Finish: Internal: SF1, 20 Ra μin (0,5 μm) standard; SF5, 20 Ra μin (0,5 Ra μm) electropolish or better optional

- Subcooling: Less than 3°F (1.7C °C)

An Overview of Steam-In-Place

A comprehensive overview of SIP, existing components, piping design, and the new technology used to reduce common problem occurrences.

Steam Trap Comparison Chart

Understanding the differences among the full line of Steriflow steam traps

- CRN (Canadian Registration Number)

- PED Category 1 (Pressure Equipment Directive)

- SEP Declaration (Sound Engineering Practice)

- ATEX Certified

- EC Declaration of Conformity

- All products use FDA and USP Class VI approved soft goods and seals where possible. Consult each product data for details

3/4″ Mark 94 Series

1″ Mark 94 Series

1-1/2″ Mark 94 Series

Notice Regarding 3D STEP Files:

The 3D STEP files provided on this website contain proprietary information and are intended solely for use by authorized customers. These files must not be used, distributed, or repurposed by third-party vendors for promotional, marketing, or any other non-customer-related activities. Unauthorized use may violate intellectual property protections and confidentiality agreements.

-

What makes the Mark 94 Series different from other steam traps?

The Mark 94 Series is specifically engineered for high-capacity clean steam applications, offering superior condensate handling capabilities, robust construction, and reliable performance in demanding pharma, biotech and food processing environments.

-

What does “high capacity” mean for steam traps?

The Mark 94 can handle significantly higher condensate flow rates than standard steam traps in the same size range, making it ideal for large steam systems, heat exchangers, and industrial processes that generate substantial amounts of condensate.

-

What is “clean steam” and why does it matter?

Clean steam refers to steam that meets pharmaceutical, biotech or food-grade standards – free from contaminants and additives. The Mark 94 is specifically designed with materials and construction that maintain steam purity and prevent contamination.

-

What if a steam trap is passing steam?

Steam passing could indicate internal wear, improper sizing or sizing conditions exceeding design parameters. Professional inspection and possible service may be needed to restore proper operation.

Your List

Email List

Get A Quote

Related Products

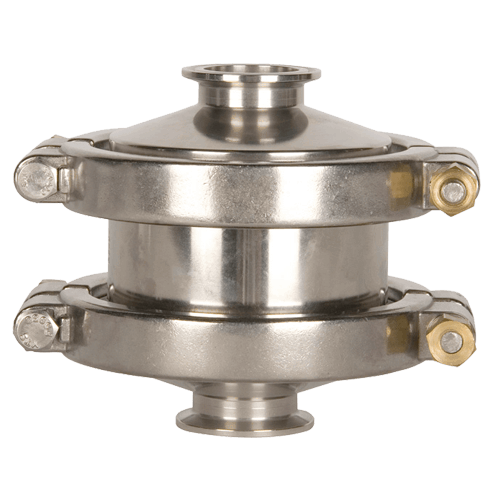

Mark 934 Series

High - ultra flow, <3°F (1.7°C) subcool operation

Mark 93 Series

Medium to high flow, <3°F (1.7°C) subcool operation

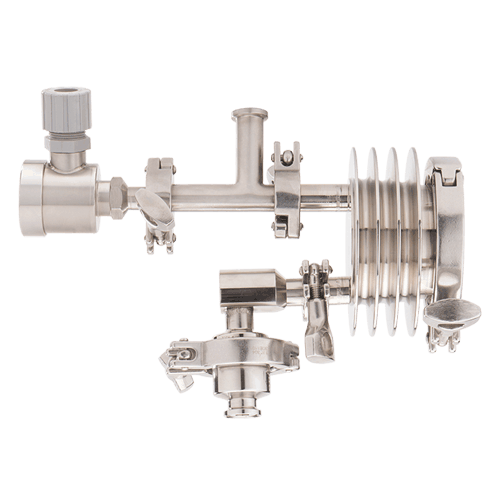

SSC Series

For compact, validated SIP sensor/steam trap drain installations

Explore our comprehensive range of Clean Steam Traps & SIP Accessories engineered for diverse sanitary applications.

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.