Buffer Dilution Pump Pressure PRV

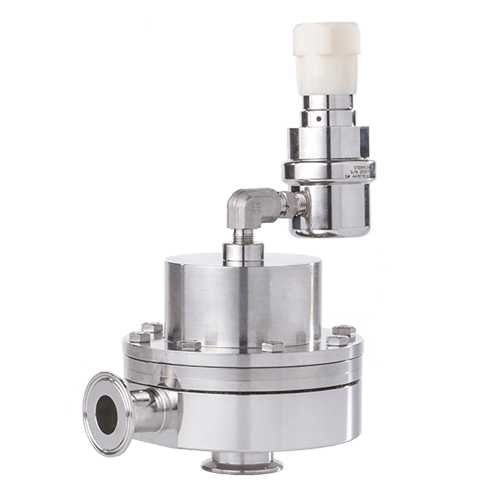

Mark 96 Series ⟶

Manual, Low to High Flow, Sanitary Pressure Regulator

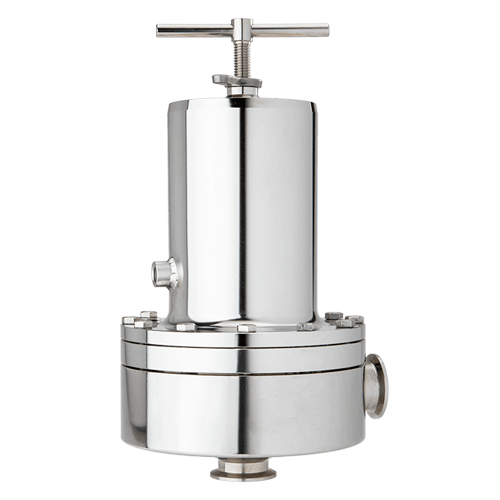

Mark 96C Series ⟶

Manual, Low to High Flow, Jorlon Diapragm

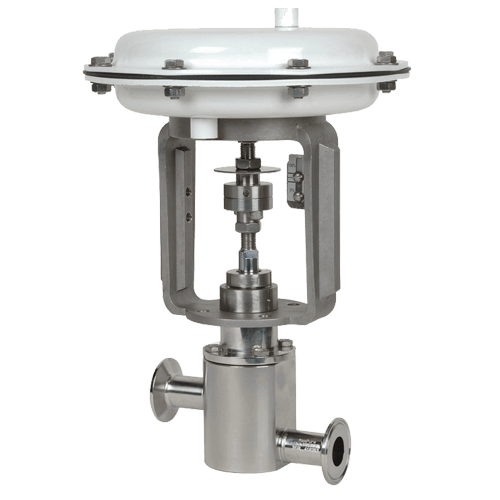

Mark 96A Series ⟶

Hybrid or Automated, Jorlon Diaphragm

Mark 96AA Series ⟶

Hybrid or Automated, Jorlon Diaphragm

Mark 978JD Series ⟶

Medium to high flow, Jorlon diaphragm

Mark 978M Series ⟶

Manual control, low to high flow, Jorlon diaphragm

Mark 978INLINE Series ⟶

Medium to High Flow, Jorlon Diaphragm

Your List

Email List

Get A Quote

In sanitary systems, maintaining stable pressure during buffer dilution is crucial for accurate results, equipment protection, and process reliability.

By integrating sanitary pressure reducing valves, and sanitary back pressure regulators, industries can achieve precise fluid pressure control, maintain consistent buffer concentrations, and optimize overall system performance.

The Buffer Dilution Pump Pressure PRV is widely applied in buffer distribution loops, point-of-use dosing, and preparation tanks, providing reliable performance across critical industrial processes.

What Is a Buffer Dilution Pump Pressure PRV?

This system works through several integrated mechanisms:

- Pressure Reduction: High pump discharge pressure is lowered to a safe setpoint using industrial pressure reducing valves or inline pressure reducing valves suitable for downstream equipment.

- Surge Absorption: Sudden pressure spikes from pump startup, flow changes, or valve closures are absorbed to protect pipelines and instruments.

- Flow Stabilization: By maintaining constant upstream pressure, the system ensures predictable flow through metering and dosing devices, supporting precise buffer concentrations.

- Hygienic Operation: The inclusion of sanitary pressure control valves and sanitary back pressure regulators ensures contamination-free operation in sterile processing environments.

Why Buffer Dilution Pump Pressure PRV Is Important

Pressure Surge Protection

Buffer dilution pumps, especially positive displacement pumps, generate pressure surges during:

- System Startup: Rapid pressure increases at initial pump activation

- Flow Adjustments: Altering dilution ratios changes flow and pressure patterns

- Valve Operations: Downstream valve closures cause instantaneous spikes

- Pump Cycling: Batch operations generate repetitive transients

A properly configured pump pressure control valve responds instantly to these events, preventing damage to pumps, piping, and instruments while maintaining consistent fluid pressure control.

Maintaining Dilution Accuracy

Accurate buffer preparation relies on steady pressure.

- Consistent flow rates through metering devices

- Stable concentration control, preventing pressure-induced variation

- Batch-to-batch repeatability

- Reduced waste by eliminating off-specification product

By using sanitary pressure control valves and pressure regulator valves, industries can achieve precise fluid pressure control that ensures high-quality, consistent buffer solutions.

Equipment Protection and Safety

Uncontrolled pressure can accelerate wear and lead to failures:

- Pump Seals: Excessive pressure can cause leaks and contamination

- Piping and Fittings: Pressure surges stress connections, welds, and valves

- Instrumentation: Flow meters, transmitters, and control valves need overpressure protection

- Operational Safety: Automatic sanitary back pressure regulators and pump pressure control valves protect personnel and maintain fail-safe operation.

Buffer Dilution Pump Pressure PRV: Key Industrial Applications

The Buffer Dilution Pump Pressure PRV is applied in systems where precise pressure management is critical:

- Pharmaceutical & Biopharma: Buffer preparation tanks, chromatography feed lines, and bioreactor dosing loops.

- Food & Beverage: CIP buffer dilution and beverage processing lines.

- Laboratories & Research: Pilot plants and laboratory buffer preparation setups

In each of these applications, the PRV maintains stable pressure, protects sensitive equipment, and ensures accurate buffer dilution. For related processes, see our Pressure Control Buffer page.

Best Practices for Buffer Dilution Pump Pressure PRV Systems

- Downstream Placement: Install the PRV immediately after pump discharge for maximum system protection.

- Proper Orientation: Ensure complete drainage during CIP cycles for sanitary pressure control valves.

- Return Line Sizing: Use a return line equal to or larger than the PRV connection to prevent backpressure.

- Structural Support: Secure valves adequately to handle reaction forces during relief.

Regular maintenance, monitoring of pump pressure control valves, and calibration of pressure regulator valves are essential to maintain optimal performance and extend system longevity.

Benefits of Buffer Dilution Pump Pressure PRV

- Smooths pressure fluctuations for accurate buffer dilution.

- Protects pumps, piping, and instrumentation from overpressure.

- Ensures consistent, repeatable buffer concentration.

- Enhances operational efficiency and reduces downtime.

- Supports hygienic operations with sanitary back pressure regulators and sanitary pressure control valves.

- Minimizes waste and off-specification product.

- Improves reliability of critical processes.

Ensuring Reliable Buffer Dilution with PRVs

The Buffer Dilution Pump Pressure PRV is essential for any system requiring accurate buffer preparation, equipment protection, and operational stability. By integrating sanitary back pressure regulators, industrial pressure reducing valves, pump pressure control valves, pressure regulator valves, inline pressure reducing valves, and sanitary pressure control valves, industries achieve precise fluid pressure control and reliable buffer distribution.

Ready to Optimize Your Buffer Dilution Pump Pressure?

Contact Steriflow Valve today to discuss how our sanitary valves can enhance your Buffer Dilution Pump Pressure.