Automation of Pharma CIP/SIP Systems with Steriflow Sanitary Valves

In the pharmaceutical industry, maintaining cleanliness and sterility is crucial to meet strict regulatory standards.

Clean in Place (CIP) and Sterilization in Place (SIP) systems ensure that equipment such as tanks and pipelines remains contamination-free between batches.

To improve efficiency, reliability, and scalability, many pharmaceutical companies prefer process automation for cleaning and sterilization.

Automation enhances consistency, reduces human error, and ensures better regulatory compliance.

When paired with advanced technologies such as Steriflow sanitary valves, automation optimizes the cleaning and sterilization processes.

This post explores how the automation of CIP/SIP systems, combined with Steriflow valves, enhances operational efficiency, compliance, and product quality in the pharmaceutical industry.

What are CIP and SIP Systems?

Clean in Place (CIP) and Sterilization in Place (SIP) are integral processes in pharmaceutical production.

Both systems are designed to clean and sterilize equipment without the need to dismantle it, thus minimizing the risk of contamination.

- CIP Systems: CIP automates equipment cleaning without disassembly. The process circulates hot water, detergents, and sanitizing agents to remove product residues from tanks, pipes, and valves. The process ensures that equipment is free from contaminants, residue, and any leftover chemicals, making it safe for the next production run.

- SIP Systems: After cleaning, the equipment is sterilized using high temperatures, steam, or chemicals to ensure that no microorganisms or bacteria are left behind.

Both processes are highly critical for maintaining product integrity, safety, and quality.

Their importance has driven the move toward more sophisticated, automated systems that ensure both thoroughness and efficiency.

Understanding Automated CIP/SIP Systems in Pharmaceutical Facilities

Automation in CIP/SIP systems typically involves sensors, controllers, and valves that work together to monitor, control, and adjust the process parameters in real-time, ensuring optimal conditions for cleaning and sterilization.

Traditionally, these systems were manually controlled, which was not only labor-intensive but also prone to inconsistencies. Today, automation brings significant improvements.

- Improved Consistency and Precision: Automation ensures that every stage of the cleaning and sterilization process is executed exactly as planned, eliminating variability and human error.

- Efficiency: Automated CIP/SIP systems can reduce cleaning times and optimize resource usage (water, cleaning agents, energy), leading to cost savings and faster turnaround times between batches.

- Regulatory Compliance: With automated systems, manufacturers can generate detailed logs of the time, flow rate and temperature of every cleaning and sterilization cycle, which are crucial for meeting compliance standards like FDA, cGMP (Good Manufacturing Practices), and ISO certifications. That data can also be directly tied to quality records for the next drug batch made in the equipment being sanitized and sterilized.

Critical Role of Sanitary Valves in CIP/SIP Automation

Valves are the decision points within every CIP/SIP system. They determine where fluids travel, when equipment is isolated, and how pressure and flow is managed during Clean-in-place and sterilization phases.

In an automated CIP/SIP system, sanitary valves must satisfy multiple performance requirements simultaneously. Internally, they must feature smooth, crevice-free flow paths and full drainability to prevent residue accumulation.

Mechanically, they must withstand repeated exposure to high-temperature steam, rapid pressure changes (sometimes including vacuum), and aggressive cleaning agents.

From an automation standpoint, valves must deliver precise, repeatable actuation to ensure that validated cleaning sequences remain consistent over time.

Failure at the valve level can undermine the integrity of the entire CIP/SIP system, leading to extended downtime, revalidation efforts, or contamination risk.

How Steriflow Sanitary Valves Enable Reliable CIP/SIP Automation

Steriflow sanitary valves, with their design and functionality, contribute to smoother, more efficient automated operations.

- Integration with Control Systems: Steriflow sanitary control valves, or air loaded pressure reducing valves integrate seamlessly with PLC/SCADA systems through pneumatic and electric actuators. Position sensors provide real-time feedback for closed-loop control, allowing facility-wide automation from a single control room. Steriflow sanitary spring actuated Pressure Reducing Valves often are the choice for automation of clean steam pressure reduction for SIP without need to connect to PLC/SCADA systems.

- Automated Clean Condensate Removal: Steriflow’s low subcooling Clean Steam traps ensure that SIP condensate is drained in a timely fashion without costly delays from temperature validation alarms.

- Automated Sequencing: A typical CIP cycle: pre-rinse with USP-PW, alkaline wash, intermediate rinse, acid wash if needed, and final WFI rinse. Each step requires precise valve positioning and flow control. For SIP cycles, automated valves control steam introduction, pressure regulation, and cooling air or gas delivery while temperature sensors confirm sterilization parameters.

- Data Logging and Validation: Automated systems log every valve position, pressure and temperature reading, flow rates, and cycle parameter. This documentation provides regulatory compliance and enables continuous improvement through performance analysis.

Benefits of Using Steriflow Valves in Automated CIP/SIP

Steriflow valves help pharmaceutical companies maintain high standards of regulatory compliance while enhancing efficiency and reducing the risk of contamination.

- Operational Efficiency: Precise flow control reduces cycle times by 15-30%. Accurate chemical dosing minimizes consumption and wastewater costs. Jorlon™ diaphragm lifetime durability warranty extends maintenance intervals from months to years, reducing spare parts inventory and unplanned downtime.

- Quality Assurance: Automated CIP/SIP with reliable valves delivers identical cycles every time. Elimination of manual valve manipulation removes human error. Steriflow Check valves prevent cross-contamination and protect product integrity.

- Regulatory Compliance: ISO 9001:2015 certified manufacturing ensures consistent quality. Steriflow valves meet the sanitary standards required by the FDA and cGMP guidelines, ensuring that every part of the CIP/SIP system is compliant with health and safety standards. Complete documentation supports validation protocols. Material

- certifications and test records satisfy GMP audits. The lifetime Jorlon™ warranty reduces change control burden.

Best Practices for Implementing Steriflow Valves in Your CIP/SIP System

Following these best practices when implementing Steriflow valves in your CIP/SIP system will ensure optimal performance and reliability.

Choose the Right Steriflow Valve Model:

Select sanitary control valves (such as the Mark 978 Series or variants), or pressure reducing valves (such as the Mark 96 series), and clean steam traps (such as the Mark 93) suited to your specific CIP/SIP flow, pressure, and media requirements.

- Match Valve Characteristics to Process Needs: Consider flow requirements (linear, equal percentage or custom trim) to ensure accurate regulation of pressure, flow rate, and other variables critical to CIP/SIP performance.

- Ensure Hygienic Construction: Use valves with polished internal surfaces and sanitary design to support smooth, crevice-free fluid paths that aid thorough cleaning and sterilization.

- Verify Material and Seal Compatibility: Confirm that wetted parts (stainless steel, FDA/USP‑Class materials) and seals are appropriate for your system’s chemicals and temperatures.

- Design for Self‑Draining and Orientation Flexibility: Implement valves with self‑draining geometry and flexible installation orientations (vertical/horizontal) to reduce residue buildup.

- Select the Right Automation Package: Choose an automation package that ensures seamless integration with Steriflow valves, providing reliable control, monitoring, and validation for your CIP/SIP processes. The automation package should include components such as control panels, positioners, and communication systems designed for the pharmaceutical industry’s regulatory standards.

- Provide Accurate Process Data for Sizing: Work with valve suppliers to supply detailed flow, pressure, and media data to ensure proper valve sizing and reliable performance.

- Implement Regular Maintenance and Testing: Establish routine inspections, calibration, and functional tests to ensure valves continue performing at peak efficiency.

Take Control of Your CIP/SIP Systems with Steriflow’s Sanitary Valves and Automation

Maximize your CIP/SIP system’s performance by choosing Steriflow sanitary valves and automation solutions. Experience unmatched precision, reliability, and seamless integration to boost your cleaning and sterilization processes. Don’t settle for less; take control of your operations today with Steriflow valves and automation packages. Get in touch now and start optimizing your pharmaceutical systems with Steriflow!

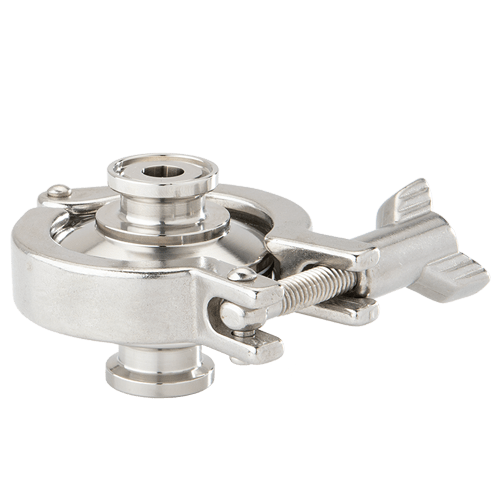

Mark 978 Series

Mark 978 Series  Mark 96 Series

Mark 96 Series  Mark 93 Series

Mark 93 Series