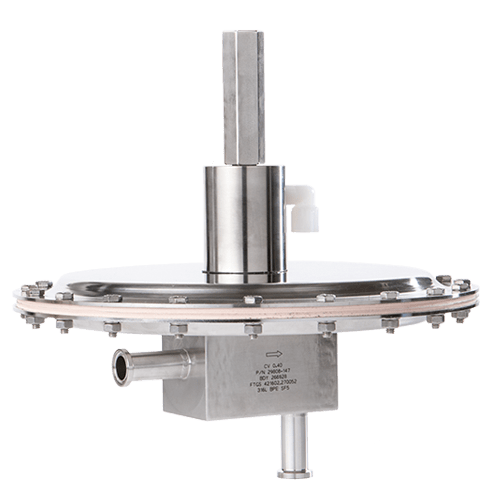

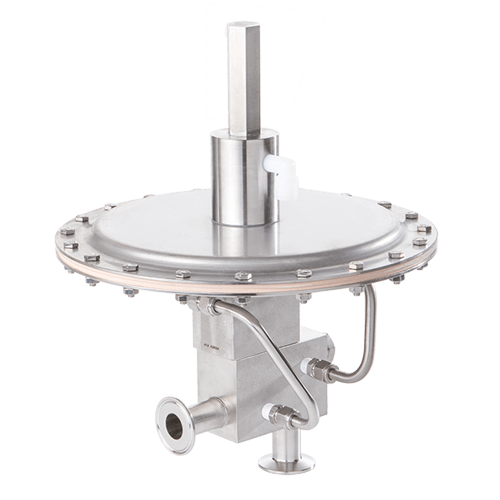

Mark 908 X Series

Barstock Construction, Low Flow, Very Low Pressure Accurate regulation down to 1/2" wc (1,25 mbar) Low pressure blanketing (gas overlay) PRV for small stainless and SUD vessels

Angle style, barstock, pressure reducing valves for regulating low flow, very low pressure clean compressed air and gas point of use applications in stainless steel and single use disposable vessels for the biopharmaceutical, pharmaceutical, food & beverage and consumer health & beauty industries.

- Small stainless steel bioreactor/fermenter: very low pressure sparge and purge/blanket/motive force gas regulation

- Small single use disposable bioreactor/fermenter: very low pressure sparge and purge/blanket/motive force or integrity testing gas regulation

- Small separation: purge/blanket/motive force gas regulation and bag integrity testing for process vessels

- Small purification: purge/blanket/motive force gas regulation and bag integrity testing for process vessels

- Small formulation: purge/blanket/motive force gas regulation and bag integrity testing for process vessels

- F & B consumer H & B process purge/blanket/motive force gas regulation

- Accurate regulation down to 1/2″ wc (1,25 mbar)

- Accurate regulation at very low flows – down to 0.15 Cv (0,13 Kv)

- Three flow coefficients to meet any of your flow requirements

- ASTM A479 316L barstock construction with ASME BPE SF5 finish standard

- All FDA and USP Class VI materials

- Optional purge feature

- ANSI Class VI shutoff

- Size: 1/2″ & 3/4″ (DN15 & DN20)

- End Connection: ASME BPE, ISO or DIN Tri-Clamp, Flanged or NPT

- Cv (Kv) 0.15; 0.2; 0.4 (0,13; 0,17; 0,35)

- Spring Ranges: 4 spring ranges from 0.5″ wc – 1.5 psi (1,24 – 103,4 mbar)

- Body/Wetted Trim Materials:

- Wetted Material: ASME SA479 316L (UNS 31603) is standard. EN 10272:2000 GR 1.4435, AL-6XN®, Hastelloy C-22 and others are optional

- Surface Finish: ASME BPE SF5, 20Ra µin (0,5 µm) electropolish

- Diaphragm: Ultra-light Teflon FDA/USP Class VI

- Seat, O-rings & Balanced Diaphragm: EPDM (FDA USP Class VI compliant), Viton (FDA compliant)

- Max Operating Inlet Pressures: 200 psig (13,8 barg)

- Max Operating Temperature: 250°F (121°C)

- Max Downstream Pressure: 20 psig (1,38 barg) (Safety Rating)

PRV Gas Regulation Comparison Chart

Understanding the differences among pressure regulating blanketing valves

- CRN (Canadian Registration Number)

- PED Sound Engineering Practice (SEP)

- All products use FDA and USP Class VI approved soft goods and seals where possible. Consult each product data for details

Your List

Email List

Get A Quote

Related Products

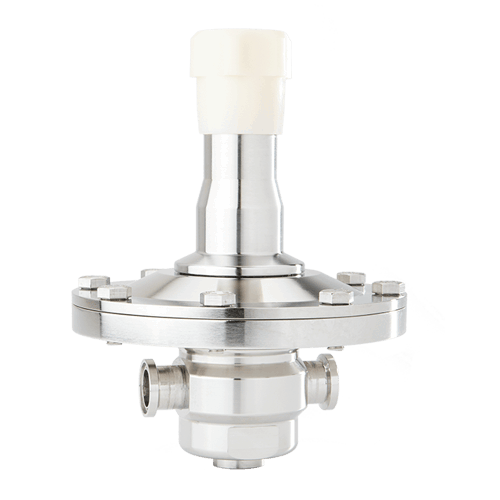

Mark 908 Series

Barstock Construction, Mid to High Flow, Very Low Pressure

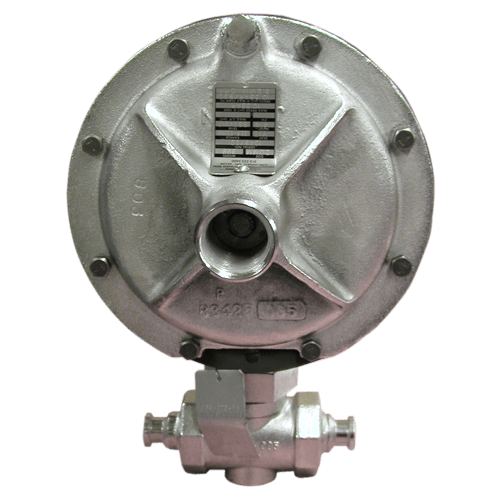

Mark 968 Series

Manual, Cast, Medium to High Flow, Very Low Pressure

JSRLP Series

Manual or Air Augmented, Low to Medium Flow, Low Pressure, Jorlon Diaphragm

Size ranges: 1/2" & 3/4"; Cv's: 0.8, 0.5

Spring range: 1-5 psi; 5-15 psi; 15-25 psi; 25-50 psi

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.