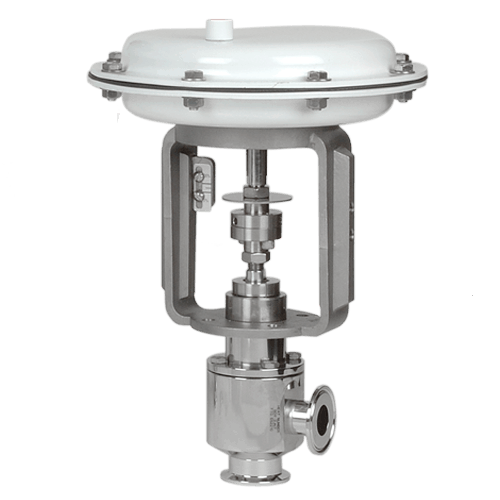

Mark 978LF-OR Series

Low flow, O-ring stem seal

Angle style sanitary control valve, for continuous precision control of gas, air, USP PW (purified water), CIP fluids in the biopharmaceutical, pharmaceutical, food & beverage and consumer health & beauty industries:

- Small vessel process input control: clean compressed air and gas

- Clean utilities: USP PW, CIP, clean compressed air and gas

- F & B and Consumer H & B process: inputs, outputs, purified water and clean utilities

- The smallest nominal flow offering in the industry. Six Cv’s between 0.005 and 0.1 enables you to control flow for any application

- Maintenance friendly – easy to perform maintenance with simple disassembly, reassembly, and steam-in-place/clean-in-place capabilities

- Mechanically and electropolished internal components – 20Ra (0,5µm) finish; others upon request

- FDA and USP Class VI conformity on all process seal materials

- Self-draining (no hold-up) – when mounted in either vertical or horizontal orientations

- Size: 1/2″ & 3/4″ (DN15 & DN20)

- End Connections: ASME, DIN and ISO tri-clamp, extended tube weld

- Cv (Kv) & Flow Characteristics: 0.005 – 0.1 (0,0043 – 0,086)

- Pressure at Maximum Temperature: 200 psi (13,8 bar) at 300°F (149°C) dependent on o-ring construction

- Wetted Material: ASME SA479 316L (UNS 31603) is standard. EN 10272:2000 GR 1.4435, AL-6XN®, Hastelloy C-22 and others are optional

- Surface Finish: ASME BPE SF5, 20Ra (0,5µm) electropolish is standard, 8Ra (0,2µm) optional

- Stem Seal – o-ring: various – all certified to FDA/USP Class VI

Jorlon Facts and Warranty

The majority of Steriflow valves come with the Jorlon diaphragm and, of course, a lifetime diaphragm warranty.

- CRN (Canadian Registration Number)

- SEP Declaration (Sound Engineering Practice)

- ATEX Certified

- EC Declaration of Conformity

- All products use FDA and USP Class VI approved soft goods and seals where possible. Consult each product data for details

Notice Regarding 3D STEP Files:

The 3D STEP files provided on this website contain proprietary information and are intended solely for use by authorized customers. These files must not be used, distributed, or repurposed by third-party vendors for promotional, marketing, or any other non-customer-related activities. Unauthorized use may violate intellectual property protections and confidentiality agreements.

Mark 978LF Series

1/2″ Mark 978LF Series with 14M Actuator

3/4″ Mark 978LF Series with 14M Actuator

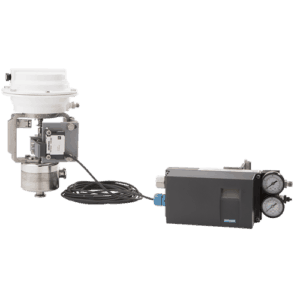

1/2″ Mark 978LF Series with Actuator and Positioner

1/2″ Mark 978LF Series with 14M and 16IP Side Positioner

1/2″ Mark 978LF Series with 14M and 16IQ Side Positioner

1/2″ Mark 978LF Series with 14M and 16PP Side Positioner

1/2″ Mark 978LF Series (Jorlon Diaphragm) with 14M and 16IP Side Positioner

1/2″ Mark 978LF Series (Jorlon Diaphragm) with 14M and 16IQ Side Positioner

1/2″ Mark 978LF Series (Jorlon Diaphragm) with 14M and 16PP Side Positioner

3/4″ Mark 978LF Series with Actuator and Side Positioner

3/4″ Mark 978LF Series with 14M and 16IP Side Positioner

3/4″ Mark 978LF Series with 14M and 16IQ Side Positioner

3/4″ Mark 978LF Series with 14M and 16PP Side Positioner

3/4″ Mark 978LF Series (Jorlon Diaphragm) with 14M and 16IP Side Positioner

3/4″ Mark 978LF Series (Jorlon Diaphragm) with 14M and 16IQ Side Positioner

3/4″ Mark 978LF Series (Jorlon Diaphragm) with 14M and 16PP Side Positioner

Mark 978LF Series with Actuator and Top Positioner

1/2″ Mark 978 Series with 14M and Top Positioner

1/2″ Mark 978 Series (Jorlon Diaphragm) with 14M and Top Positioner

3/4″ Mark 978 Series with 14M and Top Positioner

3/4″ Mark 978 Series (Jorlon Diaphragm) with 14M and Top Positioner

Your List

Email List

Get A Quote

Related Products

Mark 978OR Series

Medium to High Flow, O-ring Stem Seal

Mark 16IQ Series

Side Mounted I/P

The Mark 978LF-OR Series is an angle-style sanitary control valve for precise low-flow control of gas, air, USP PW, and CIP fluids in biopharma and food & beverage industries.

Get Help Sizing Your Valve

Quickly and accurately determine the flow coefficient of a valve so that you can choose the proper Steriflow valve for your application.