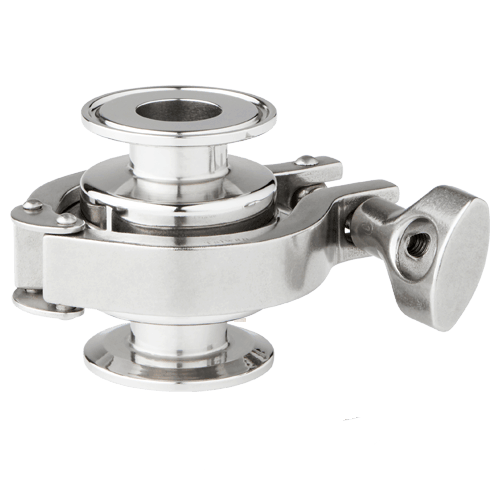

SHC Series

Horizontal line, Low to High Flow, Springless, Crevice-Free

Two piece, spring-less horizontal line sanitary check valve for bioprocess media and purified water applications for the biopharmaceutical, pharmaceutical, food & beverage and consumer health & beauty industries:

- WFI loop: non-return at pump out

- Media/buffer prep: back flow prevention during dilution

- Upstream process: sparge line back flow prevention

- Separation: centrifuge waste line back flow prevention

- Purification, chromatography: waste line back flow prevention

- Pump head pressure maintenance or pressure bypass

- F & B and consumer H & B process inputs, outputs, purified water and clean utility back flow prevention

- Removal of traditional spring and stem guide:

- eliminates areas where bioburden and bacteria can accumulate

- potential for particulate generation

- No hold up

- High flow rates with minimal pressure loss an increased flow compared with mechanical return check valves.

- Very low cracking (opening) pressure

- Size: 1/2″ – 2″ (DN15 – DN50)

- End Connections: ASME, DIN, ISO Tri-Clamp and Tube Weld Ends

- Cv (Kv): 3.4 – 23.1 (2,94 – 20)

- Max Pressure/Temperature: 230 psi @ 100°F (16 bar @ 38°C) (Max temperature dependent on seal and disc selection)

- Wetted Material: ASME SA479 316L (UNS 31603) is standard. EN 10272:2000 GR 1.4435, AL-6XN®, Hastelloy C-22 and others are optional

- Disc Material: 316/EPDM, Teflon, PEEK (all materials are FDA and USP Class VI)

- O-ring Material: Various, all materials are FDA and USP Class VI

- Cracking (opening) Pressure: Polymer Discs: 0.04 psid (2,76 millibar); 316/EPDM: 0.13 psid (8,76 millibar)

- Metallic Surface Finish: Wetted parts: ASME BPE SF5 (20 Ra μin (0,5 Ra μm) electropolished; standard: 8 Ra μin (0,2 Ra μm) electropolished optional

What are the Cracking Pressures for SVC/SHC Sanitary Check Valves?

Need to know the cracking pressures available for our springless sanitary check valves?

An Overview of Steam-In-Place

A comprehensive overview of SIP, existing components, piping design, and the new technology used to reduce common problem occurrences.

- CRN (Canadian Registration Number)

- PED Category 1 (Pressure Equipment Directive

- SEP Declaration (Sound Engineering Practice)

- ATEX Certified

- EC Declaration of Conformity

- All products use FDA and USP Class VI approved soft goods and seals where possible. Consult each product data for details

Notice Regarding 3D STEP Files:

The 3D STEP files provided on this website contain proprietary information and are intended solely for use by authorized customers. These files must not be used, distributed, or repurposed by third-party vendors for promotional, marketing, or any other non-customer-related activities. Unauthorized use may violate intellectual property protections and confidentiality agreements.

Horizontal Check Valve with Tri-Clamp Ends

1/2″ SHC with Tri-Clamp Ends

3/4″ SHC with Tri-Clamp Ends

1″ SHC with Tri-Clamp Ends

1-1/2″ SHC with Tri-Clamp Ends

2″ SHC with Tri-Clamp Ends

Horizontal Check Valve with Tube Ends

1/2″ SHC with Tube Ends

3/4″ SHC with Tube Ends

1″ SHC with Tube Ends

1-1/2″ SHC with Tube Ends

2″ SHC with Tube Ends

Vertical Check Valve with Tri-Clamp Ends

1/2″ SVC with Tri-Clamp Ends

3/4″ SVC with Tri-Clamp Ends

1″ SVC with Tri-Clamp Ends

1-1/2″ SVC with Tri-Clamp Ends

2″ SVC with Tri-Clamp Ends

2-1/2″ SVC with Tri-Clamp Ends

3″ SVC with Tri-Clamp Ends

Vertical Check Valve with Tube Ends

1/2″ SVC with Tube Ends

3/4″ SVC with Tube Ends

1″ SVC with Tube Ends

1-1/2″ SVC with Tube Ends

2″ SVC with Tube Ends

3″ SVC with Tube Ends

Your List

Email List

Get A Quote

Related Products

SVC Series – Up-Flow

Vertical Line Up-Flow, Low to High Flow, Springless, Crevice-Free

SVC Series – Down-Flow (Liquids only)

Vertical Line Down-Flow - For Liquid Drain Lines, Low to High Flow, Springless, Crevice-Free

Explore our comprehensive range of Sanitary Check Valves engineered for diverse industrial applications.

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.