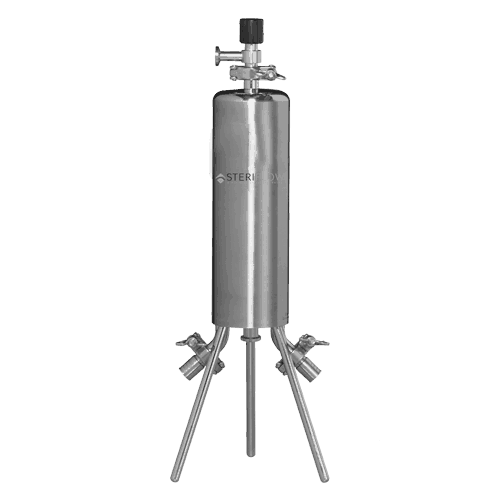

SV Series

The Sample Valve is specifically designed to precisely control the flow of fresh clean steam or hot WFI into a sample cooler

The SV Series was designed for use in high purity steam systems and water systems. The SV utilizes a steam resilient Perlast® seat seal and stem seal to ensure optimum service life and bubble tight shut-off. Because of these design characteristics, the SV is also used for any general pharma sampling application where a manual valve is required.

- WFI, USP PW (purified water), or Clean Steam sample cooler metering valve

- Upstream process: sample valve or metering for bioreactor additives

- Downstream process: sample valve for process analysis

- Media prep: sample valve or manual additive metering valve

- F & B Consumer H & B sample valve for additive or final process fluid analysis

- Fully drainable when installed with handle facing up or on it’s side

- Compact design

- Autoclavable

- Suitable for CIP and SIP

- Fine stem threads for precision metering

- SFI surface finish

- Size: 1/2″ & 1″ (DN15 & DN25)

- End Connections: ASME BPE Tri-clamp compatible

- Max Pressure: 116 psig (8,0 barg)

- Max Temperature: 347°F (176°C)

- Materials of Construction: Body and wetted stem: 316L; Seat Seal: Perlast (FFKM), FDA and USP Class VI compliant; Stem Seal; Viton, FDA and USP Class VI compliant; Handle: Plyethermide (Autoclavable)

- Wetted Surface Finish: ASME BPE SF1 20 Ra μin (0,5 μm) is standard, SF5 optional

- External Surface Finish: Satin 32 Ra uin (0,8 Ra um) mechanical finish is standard; Electropolish optional

Your List

Email List

Get A Quote

Related Products

SC30 Series

Sample Coolers

SC50 Series

Permanent and Portable Installation

SC60 Series

Permanent and Portable Installation

Explore our comprehensive range of Sample Coolers engineered for diverse industrial applications.

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.