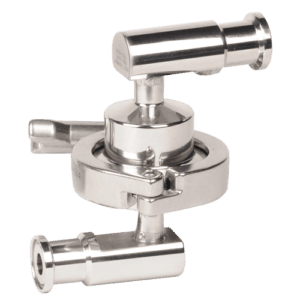

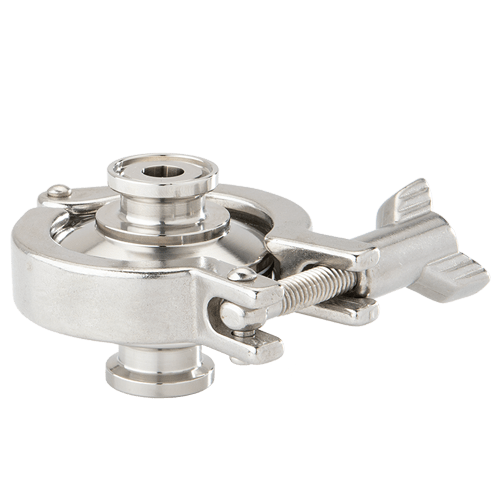

Mark 93 Series

Medium to high flow, <3°F (1.7°C) subcool operation

Two piece tri-clamp body, balanced port, medium high flow thermostatic sanitary steam trap with vertical or horizontal inlet and outlet connections for pure steam SIP and loop drainage applications in biopharmaceutical and aseptic food & beverage and certain consumer health & beauty industry applications.

- Up and downstream process vessel: small to medium sized vessel, or large vessel bypass loop trap, validated SIP drainage applications

- Up and downstream process: validated SIP tubing drain applications

- Sterile filter: validated SIP condensate drain from filters

- Clean steam distribution: loop drainage and point of use PCV drainage applications

- Clean steam humidification drainage in air handlers

- Low subcooling operation reduces probability of SIP delays caused by temperature validation faults

- Lay-in dimension allows drop in replacement of higher subcool, competitive traps

- Easy thermal element (bellows assembly replacement only installs in one direction) error-proof

- New design provides excellent flow rates with low subcooling – improves heat-up drainage

- Self-draining when installed vertically (body outlet side down) – either vertical or horizontal connections

- Solid barstock body with fewer cracks and crevices than competitive designs

- Size Range: 1/2″, 3/4″, 1″, 1-1/2″ (DN15, DN20, DN25, DN40)

- Installation Connection Orientation: Vertical, Horizontal

- Connection Type: ASME, DIN, ISO Tri-Clamp and Tube Weld Ends

- Maximum Pressure Temperature: 145 psig (10 barg) @ 350°F (177°C)

- Max. Recommended Differential Pressure: MK93: 10 – 50 psi (0,7 – 3,4 bar); MK93 Option P: 45 – 90 psi (3,1 – 6,2 bar)

- Materials of Construction: Wetted body/plug material: ASTM A479 316L or optional DIN 1.4435; Body Gaskets: Various – all FDA and USP Class VI

- Nominal Cv (Kv): 3.8 (3,30)

- Surface Finish: Internal: SF1, 20 Ra μin (0,5 μm) standard; SF5, 20 Ra μin (0,5 Ra μm) electropolish or better optional

- Subcooling: Less than 3°F (1.7°C)

Steam Trap Comparison Chart

Understanding the differences among the full line of Steriflow steam traps

Product Overview Videos

Learn about some of the features and benefits of our most popular products.

- CRN (Canadian Registration Number)

- SEP Declaration (Sound Engineering Practice)

- All products use FDA and USP Class VI approved soft goods and seals where possible. Consult each product data for details

1/2″ Mark 93C Series Step File

3/4″ Mark 93C Series Step File

1″ Mark 93C Series Step File

1-1/2″ Mark 93C Series Step File

Notice Regarding 3D STEP Files:

The 3D STEP files provided on this website contain proprietary information and are intended solely for use by authorized customers. These files must not be used, distributed, or repurposed by third-party vendors for promotional, marketing, or any other non-customer-related activities. Unauthorized use may violate intellectual property protections and confidentiality agreements.

-

Can you test clean steam traps to ensure that they are operating correctly?

Balanced port thermostatic clean steam traps can only be tested during SIP temperature hold. During heat-up, the traps are wide open, draining the relatively cooler condensate and air from the system. During temperature hold condensate loads are much less, causing the traps to frequently cycle open and closed depending upon the temperature of the condensate. Hot condensate (at or near steam saturation temperature) will expand the trap’s liquid filled bellows, causing the plug to seat in the trap orifice until the condensate cools enough below saturation temperature for the bellows to contract, allowing condensate to drain through the orifice. Typically, traps will cycle open -> close every few seconds to a few minutes depending up the temperature hold condensate load. It is during this period of continual cycling that traps can be tested with an ultrasonic leak detector by placing the leak detection probe on the trap inlet. Every time the trap opens, the condensate can clearly be heard passing through the trap orifice. Balanced port thermostatic traps fail in the open position. So if no cycling is heard, the trap is not functioning properly, indicating that either condensate is continually passing through the orifice (failed bellows) or the orifice is plugged and flow is stopped or slowed. Note that a failed trap attached to a condensate manifold connected to adjacent traps (common on process skids), can cause temperature validation faults in the adjacent traps. A failed, open trap will allow the pressure in the condensate manifold to increase, slowing the flow of condensate through the adjacent traps causing condensate levels to rise and cool the temperature validation sensors.

-

Why is low subcooling an important feature in a validated SIP process trap?

If subcooled condensates backs up more than 12-18″, it will wet and cool the SIP validation temperature sensor. Most SIP protocols are violated if the validation temperature sensor measure a temperature decrease of more than .5°C (called a temperature fault). SIP must be stopped, and the fault discovered and corrected before SIP can be continued. This usally results in a minimum of one hour delay in the start of the next batch.

Your List

Email List

Get A Quote

Related Products

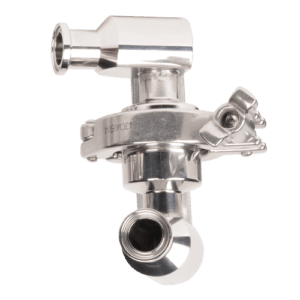

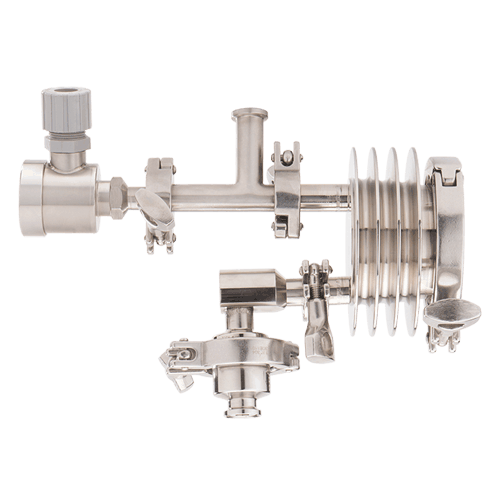

SSC Series

For compact, validated SIP sensor/steam trap drain installations

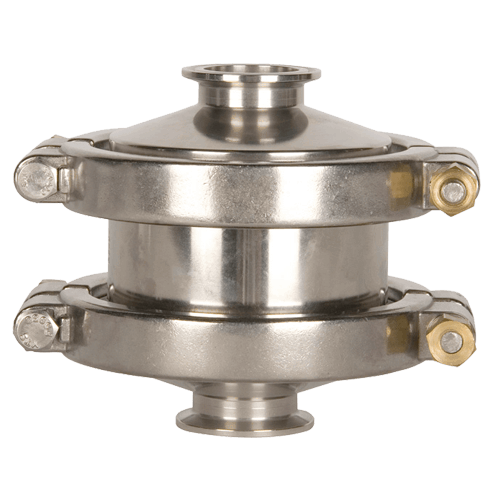

Mark 934 Series

High - ultra flow, <3°F (1.7°C) subcool operation

Mark 93JR Series

Compact, Low to Medium Flow, <3°F (1.7°C) Subcool Operation

Explore our comprehensive range of Clean Steam Traps & SIP Accessories engineered for diverse sanitary applications.

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.