Flow Control (Buffer)

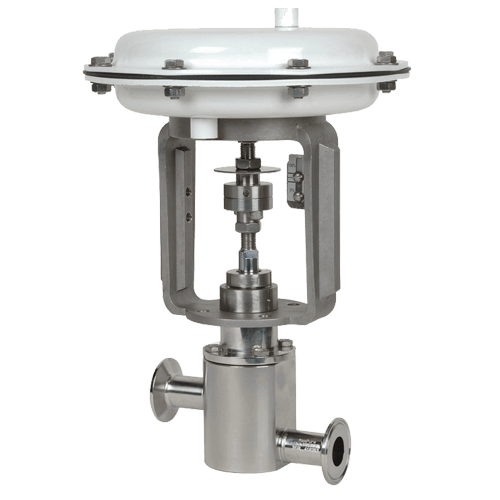

Mark 978JD Series ⟶

Medium to high flow, Jorlon diaphragm

Mark 978M Series ⟶

Manual control, low to high flow, Jorlon diaphragm

Mark 978INLINE Series ⟶

Medium to High Flow, Jorlon Diaphragm

Your List

Email List

Get A Quote

Maintaining consistent and precise fluid flow is crucial for product quality, operational efficiency, and safety. A flow control buffer acts as a stabilizing element, absorbing upstream fluctuations while delivering steady flow to downstream processes.

By controlling pressure variations and smoothing flow, flow control buffers allow operators to achieve repeatable, efficient, and safe operations. Whether in sterile biopharmaceutical production, or food and beverage processing, these buffers protect sensitive instrumentation and reduce contamination risks.

Why Flow Control Buffers Are Critical

Industrial systems often face challenges such as:

- Pressure surges that can damage pumps, meters, or valves

- Flow variability leading to inconsistent batch quality

- Turbulence in sanitary applications increasing contamination risk

- Precision-sensitive processes like fermentation or chromatography

A flow control buffer provides the cushioning and control needed to maintain stable flow, ensuring that critical processes operate efficiently and safely.

Key Applications of Flow Control Buffers

- Biopharmaceutical Flow Control

- Stable delivery of buffers, media, and reagents during filtration, formulation, and chromatography.

- Reduces variability to maintain consistent batch quality.

- Protects sterile systems from sudden surges, ensuring product integrity.

- Food & Beverage Flow Control

- Maintains hygienic, steady flow in dairy, brewing, and beverage production.

- Reduces turbulence to preserve product quality and compliance.

- Supports high production throughput with minimal downtime.

Benefits of Using a Flow Control Buffer in Your Process

Integrating a flow control buffer with the right valves enhances critical operations across industries. Key advantages include:

- Stable and consistent flow: Absorbs upstream fluctuations and delivers precise flow to downstream processes.

- Equipment protection: Shields pumps, meters, and sensitive instruments from pressure surges and flow variability.

- Improved process consistency: Reduces batch-to-batch variability in biopharma, chemical, and food & beverage operations.

- Optimized throughput: Supports high production rates with minimal disruptions.

- Lower contamination risk: Maintains hygienic conditions by minimizing turbulence in sanitary processes.

- Simplified maintenance: Reduces wear on valves and equipment, extending service life and reliability.

By combining flow control buffers with carefully selected Steriflow valves – such as the 978jd, 978m, and 978inline series – operators can achieve precise, safe, and efficient process control without compromising product quality.

Ready to Optimize Your Process Flow?

A flow control buffer ensures your critical processes remain stable, efficient, and safe. By integrating Steriflow valves, operators can achieve precise flow regulation and improved operational reliability.

Contact Steriflow to explore the 978jd, 978m, and 978inline series and discover how these solutions can enhance your process efficiency and product quality.