When to Use a Safety Relief Valve or a Rupture Disc

RELIEF VALVE or RUPTURE DISC – What is right for your sanitary process?

Understanding Pressure Protection in Manufacturing

Keeping people and processes safe from overpressure events is extremely important in manufacturing facilities. In certain situations, designers are required to specify safety mechanisms to relieve pressure if overpressure occurs. Rupture discs and safety relief valves are both used for this purpose.

What is a Rupture Disc?

A rupture disc, sometimes called a bursting disc, is a safety device that protects piping, vessels, and other equipment from excessive pressure or vacuum. It is a thin slice of metal that has been scored in order to burst at a predefined pressure, releasing pressure to prevent injury or damage. By definition, a rupture disc is a one-time use safety device.

What is a Safety Relief Valve?

A safety relief valve or pressure relief valve is a type of safety valve used to control or limit the pressure in a system. Pressure might otherwise build up and create a process upset, instrument or equipment failure or fire. The obvious difference between a relief or safety valve and a rupture disc is that the valve reseats and the disc does not.

Safety Relief Valve vs Rupture Disc: Pros and Cons Comparison

Rupture Disc Advantages and Disadvantages

Pros:

- Lower initial purchase price

- Smaller, more compact device compared to safety relief valves

- Suitable for rare, sudden overpressure events

Cons:

- One-time use only – breaks into pieces after rupture

- Process stops until replacement is installed

- Fragments could harm equipment

- Process media exposed to atmosphere

- Not ideal when equipment downtime is a concern

Safety Relief Valve Benefits and Limitations

Pros:

- Reusable design for long-term cost savings

- Designed to relieve excess pressure, reseat, and return to service

- Minimizes damage to other system components

- Longer useful life despite higher initial capital outlay

Cons:

- Higher upfront investment

- Larger footprint requirement

Sanitary Safety Relief Valves for Biopharma Applications

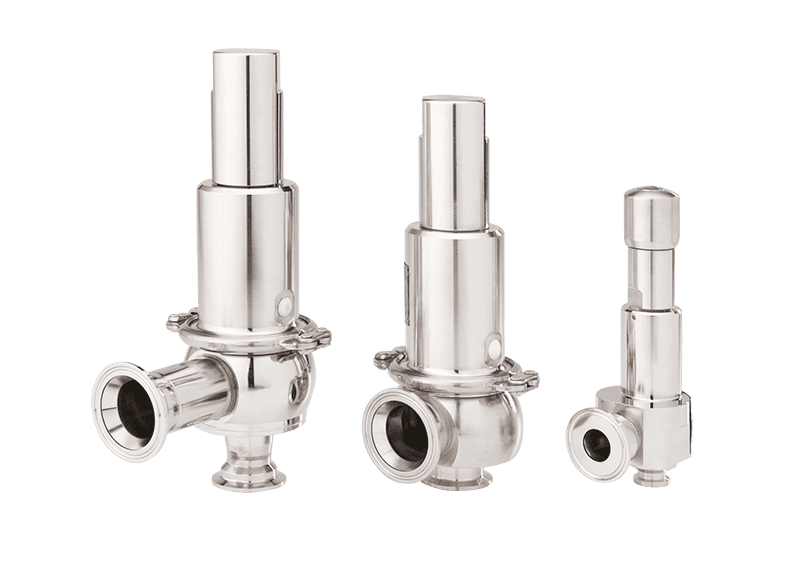

Steriflow Sanitary Safety Relief Valves (SSRV Series)

Steriflow Valve makes a sanitary safety relief valve National Board Certified to ASME VIII/XIII for overpressure protection. They are designed for the same purpose as a standard safety relief valve but have sanitary specifications for biopharma applications.

The Steriflow Sanitary Safety Relief Valves (SSRV Series) are designed to relieve over-pressure activity in hygienic and aseptic processes and clean utility systems. They are manually set to open at a predetermined pressure and re-seat after pressure subsides. This protects pressure vessels and other equipment from pressure that exceeds their design limits.

Key SSRV Features

Specific SSRV features include:

- High cleanability (L/D < 1.5)

- 20 Ra µin (0,5 Ra µm) surface finish

- Electropolished surfaces

- FDA and USP Class VI wetted parts

- Optional manual or pneumatic lift device for Clean-in-Place

- Bellows seal that isolates process from valve internals on some models

Applications Where Safety Relief Valves (SSRV) Are Used Include:

- Single use or stainless steel vessel pressure relief

- Clean air and gas point-of-use (POU) pressure relief

- Lyophilizer clean steam pressure relief

- Bioreactor – fermenter vessel and vessel jackets

- Formulation and other pharma process vessels

- Clean steam systems

- WFI and USP PW vessels

Frequently Asked Questions

Which is more cost-effective: safety relief valve or rupture disc?

Rupture discs have lower upfront costs but require replacement after each activation. Safety relief valves have higher initial costs but offer long-term savings through reusability.

When should I choose a rupture disc over a safety relief valve?

Choose rupture discs for rare overpressure events where equipment downtime isn’t critical and when space constraints require a compact solution.

Can safety relief valves be used in sanitary applications?

Yes, sanitary safety relief valves like the SSRV Series are specifically designed for biopharma applications with FDA-compliant materials and cleanable designs.

Making the right choice for your sanitary process

Are you considering overpressure control for your sanitary process? View our SSRV product Line for specifications and certifications.

How Can We Help You With Your Sanitary Processes?

Contact us to learn more about how an SSRV can protect your sanitary process

Sanitary Safety Relief Valves

Sanitary Safety Relief Valves