What is the Function of Clean Gas Pressure Reducing Valves (PRVs)?

Application: Upstream – Cell Culture – Incubators, Bioreactors

Media: Clean Air and Gas

Valve Requirement: Pressure Control – PRV

What is the function of Clean Gas Pressure Reducing Valves (PRVs)?

Pressure Reducing Valves (PRV’s) control the pressure downstream of the valve, at the valve outlet. They are mechanical devices that automatically reduce high inlet pressure to a lower, constant outlet pressure.

In Cell Culture applications, Clean Gas PRVs reduce the pressure from the Clean Air and Gas Distribution lines to levels suitable for Incubators, Seed Bioreactors, or Production Bioreactors.

How do Pressure Reducing Valves work?

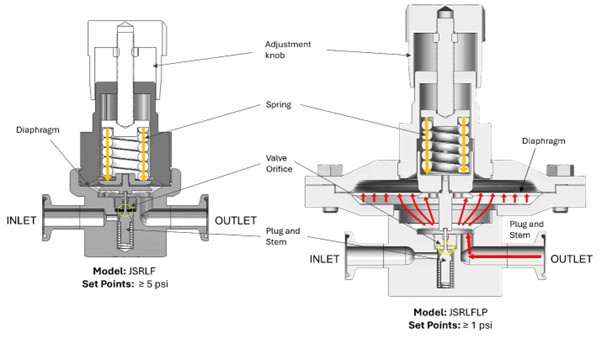

With clean air or gas flowing through the valve, turn the adjustment knob on top of the PRV to change the spring compression which determines pressure setpoint for the outlet pressure.

- To set the valve at an appropriate outlet pressure, rotate the adjustment knob until the ideal outlet pressure setpoint is achieved. Once the PRV is set, the valve will maintain that downstream pressure setpoint because the spring force and outlet pressure are in equilibrium.

- Rotating the adjustment knob clockwise increases spring compression and moves the diaphragm and attached stem and plug downward causing the valve to open further. This allows more gas downstream raising the outlet pressure.

- A counter-clockwise knob adjustment lowers the outlet pressure.

Once set, the outlet pressure decreases, the spring force will be greater than the outlet pressure and the valve’s stem and plug will automatically move downward – opening to increase the flow/pressure downstream to rebalance that setpoint equilibrium.

Conversely, if the pressure at the outlet increases, the valve’s stem and plug will move in the closing direction – decreasing downstream flow/pressure to maintain that setpoint equilibrium.

Why is pressure control of clean gas important in cell culture applications?

Accurate pressure control of clean air and gases is critical in cell culture applications because cells are highly sensitive to their physical and chemical environment. Even small deviations in pressure can alter this sensitive environment and ultimately affect the biomolecule yield or titer.

Accurate pressure control of clean air and gases is essential for cell culture processes because it:

- Keeps oxygen, CO₂, and pH levels stable

- Protects sensitive cells from shear stress

- Ensures batch-to-batch reproducibility

- Maintains sterility

- Enables precise low-flow delivery

- Supports regulatory compliance

Steriflow Valve can help with your cell culture applications

Steriflow Valve offers a full range of Clean Air and Gas Pressure Reducing Valves to provide critical pressure control for cell culture operations. Contact us to find the right one for your application.

JSRLF Series

JSRLF Series  JSRLFLP Series

JSRLFLP Series