What is a Sanitary Subcooled Condenser?

What are the benefits of a sanitary subcooled condenser and how does it work?

The Sanitary Subcooled Condenser is designed to optimize steam-in-place (SIP) systems by reducing condensate backup, protecting temperature sensors, and improving overall heat-up efficiency.

What Are the Benefits of a Sanitary Subcooled Condenser?

There are three significant user benefits for the SSC Series:

- Allows the installation of temperature validated sensor/drip leg/trap assemblies in tight places where there isn’t enough room to install the traditional 12″ – 18″ (300mm – 460mm) drop leg between the validation sensor and trap

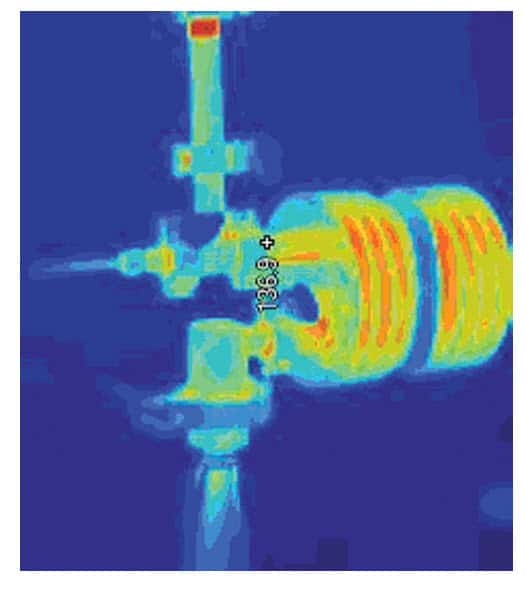

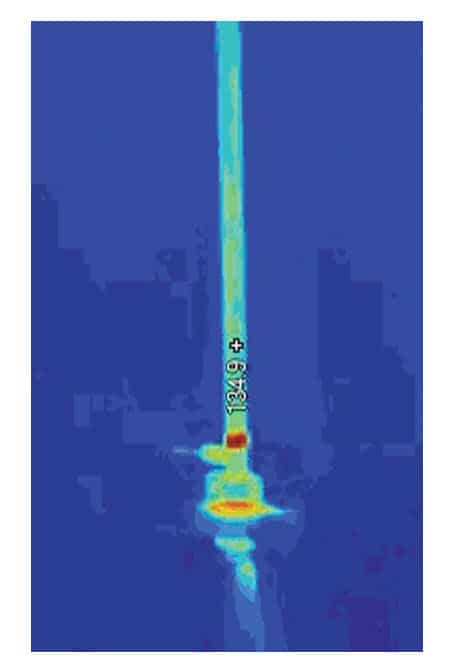

- The SSC is a large, finned, volume collection chamber for the accumulation of condensate downstream of the validation temperature sensor, up stream of the trap. The SSC’s large volume chamber eliminates the possibility that condensate will back up and wet and cool the temperature sensor

- The SSC subcools condensate before it enters the thermostatic steam trap, contracting the bellows and further opening the trap orifice. This results in a significant increase in the traps ability to drain condensate quickly, lessening heat up time.

Why the SSC Outperforms Traditional Downcomers

The SSC Series has 5 times more radiant surface area than an 18″ downcomber. The fins allow ambient air to completely enfold the SSC. The air is heated, rises and is displaced by cooler air from below. The radiant and convective heat loss combine to subcool entering condensate approximately 30°F (17°C). The temperature difference causes the trap bellows to contract allowing a substantial increase in flow.

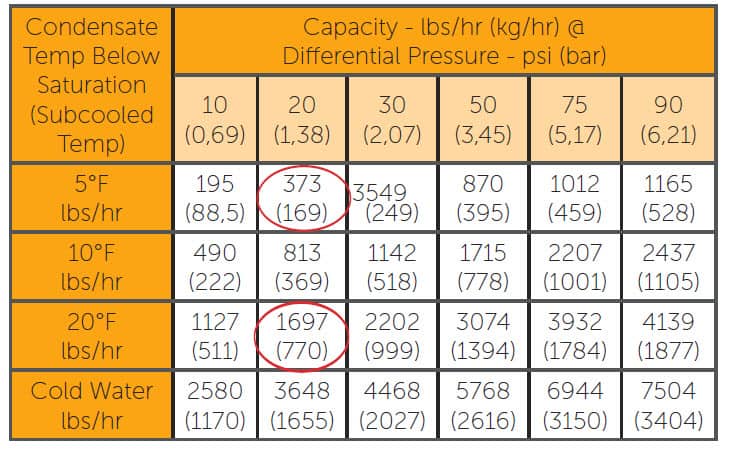

While manufacturers don’t publish steam trap capacities at 30° subcooling, we do publish capacities at 20°F. With SIP steam pressures of 20 psi (1,4 bar) the trap condensate capacity increase when condensate is subcooled on 20°F (11°C) is about 1323 lbs/hr (601 kg/hr). This significant increase in drainage capacity lessens heat up time.

The Proof: A multinational Pharma company informed us that they tested the SSC on fixed and mobile formulation vessels and decreased heat up times by an average of 10 minutes.