What Are Some Tools to Mitigate Common SIP Problems?

What do SIP problems have in common? Lost production and revenue!

There are three common problems encountered during SIP:

- Temperature hold validation alarms

- Slow condensate drainage

- Not getting up to temperature, or not getting up to temperature fast enough (slow heat-up)

What do all of these problems have in common? Lost production and revenue!

The majority of temperature hold validation alarms can be corrected or prevented by doing one or more of the following:

- Replacing failed traps on multiple trap headers when they fail

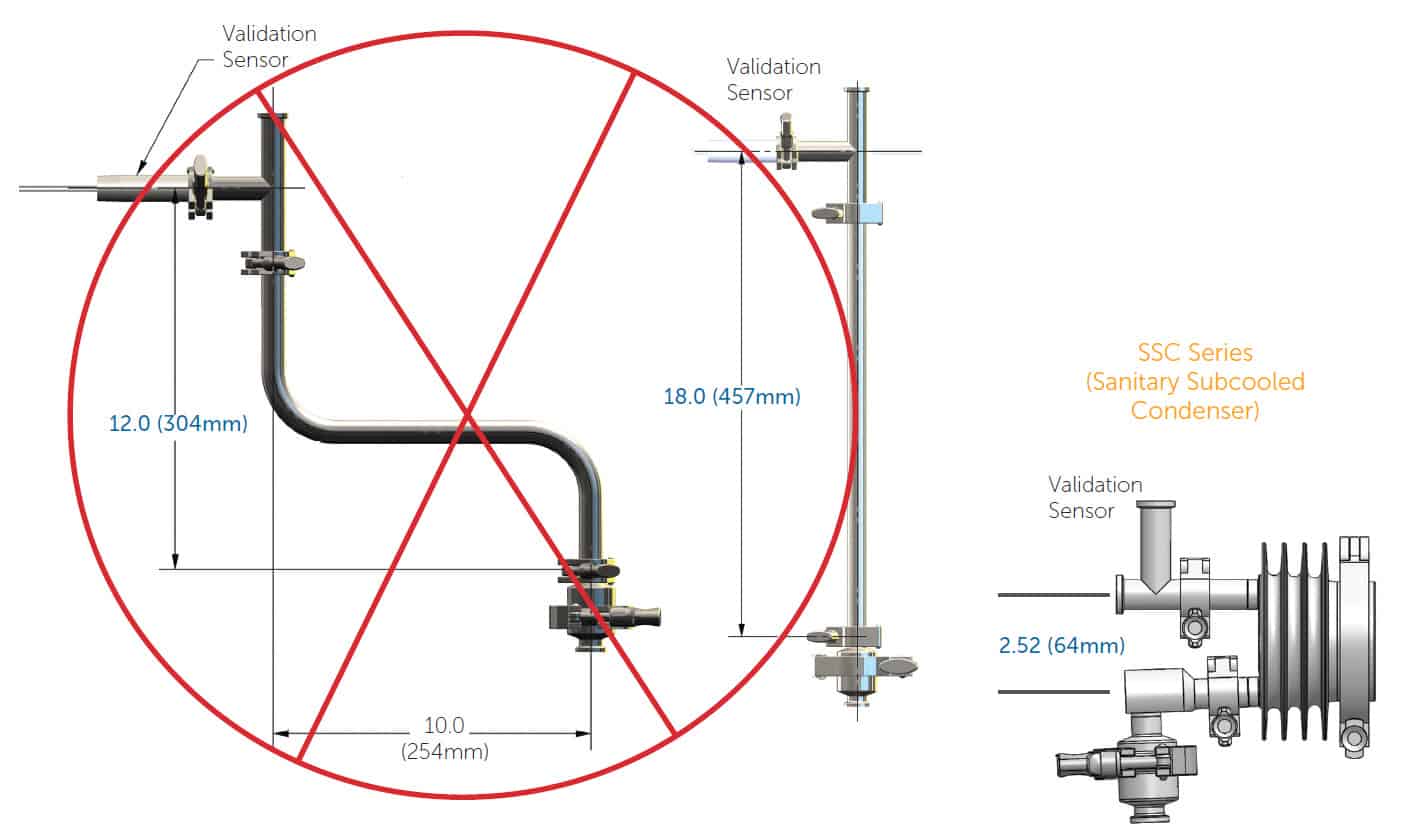

- Making sure there is about 12″ – 18″ (300mm – 450mm) of 3/4″ tubing between the trap and temperature sensor to hold condensate back up

- And, most importantly, installing properly sized traps in your temperature validated drain tubing that operate at low subcooling temperatures to minimize condensate back up

However, there are compact installations, particularly under vessels and equipment, where it is not possible to install a vertical and horizontal downcomber (drop leg) of sufficient length to prevent condensate from backing up and wetting the sensor. Secondly, there are some installations, where because of incorrect piping design or unforeseen condensate load variations, that the load overwhelms the condensate leg and the trap. What do you do in these situations?

There are two fixes for the tight space problem:

If you don’t have the height for a required run of vertical tubing, increase the horizontal distance. The trick is to put a volume buffer in the tubing between the trap and sensor. As long as there is enough tubing slope to quickly drain and prevent condensate from reaching the sensor, distance will do the trick. Why not have a horizontal run of 20″ (500mm) (err on the conservative side) and a vertical drop of 4″? Your tubing technician or contractor might have to get imaginative with his bends where the real estate is tight, but as long as there is enough vertical run to keep the condensate from touching the sensor, the tubing volume is the key.

If you don’t have the height or horizontal space to install any significant horizontal or vertical tubing (or, you are not inclined to do so), you may want to install a newer product that was developed a few years ago specifically for tight installations, for eliminating validation temperature alarms, and for improving condensate drainage: the SSC Series by Steriflow Valve.

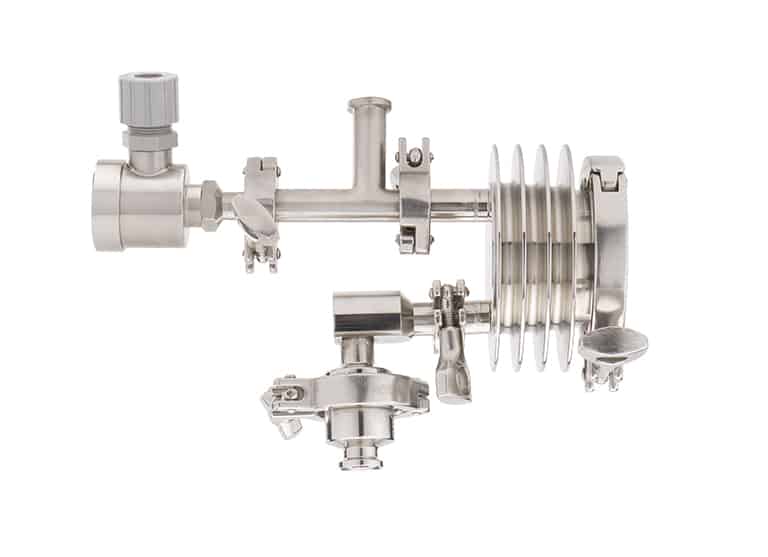

The SSC is an acronym for Sanitary Subcooled Condenser. It’s an appropriate name, as it is a compact, finned, gravity drainable, condensate holding chamber that gets installed immediately downstream of the temperature validation sensor, upstream of the trap. In addition to optimizing skid real estate, the SSC eliminates the possibility for validation temperature alarms and improves condensate drainage.