Single-Use Bioreactor Bag Integrity Testing

Application: Upstream and Downstream Single-Use Process

Media: Clean Air and Gas

Valve Requirement: PRV and BPRV Single-Use Bag Integrity Testing

How are Single-Use Bioreactor and Process Bags Tested for Integrity Prior to Liquid Filling?

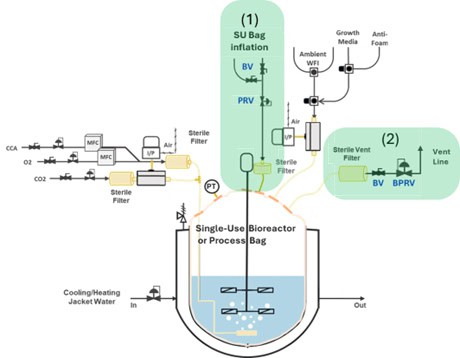

Large single-use (SU) bioreactor bags and process bags are usually tested in situ in their outer support container by inflating with clean gas prior to filling with Ambient WFI or process fluids. This integrity testing ensures that the bag gently and safely unfolds without leakage at its maximum allowable operating pressure.

The single-use process bag test media is usually Clean Compressed Air or N2.

- Smaller bags up to 2000L usually have a max allowable pressure of 0.5 psig, so the inflation test pressure will be ≤ that.

- Larger bags up to 4000L may have maximum allowable pressures up to 5 psig, with a 1 psig max recommended inflation test pressure.

Most SU manufacturers supply an outer support container for the SU bag. They either manufacture or procure the SU tube sets and fluid control instrumentation for the targeted process including those used for bag integrity testing.

If an engineer is designing their own single-use systems from purchased components, the set-up for single-use bag inflation is relatively simple and similar to the illustration shown below.

Valves for Single Use Bag Inflation Testing

The setup will require a pressure reducing valve (PRV) as a feed valve and a back pressure regulating valve (BPRV) as a vent valve. The PRV will be installed in the stainless-steel clean utility air or gas line supplying the suite, upstream of a sterile filter. The BPRV is typically installed in the vent line downstream of the sterile vent filter as shown in the highlighted region.

PRV: The best PRV will be stainless steel with a large diameter diaphragm to enable the very low pressure set points required for inflation. See our full range of Low Pressure Blanketing Regulators.

BPRV: If installed in the typical configuration downstream of the sterile vent filter, the best BPRV will be either a manual, stainless-steel, large diaphragm valve, or an automated, smaller, air-loaded valve. If extreme accuracy or automation is required for this installation, we would recommend an air-loaded valve, used either in manual mode or automated with an I/P. See our full range of Low Pressure Blanketing Regulators.

Upstream BPRV: If the BPRV is installed upstream of the sterile vent filter in the single- use tube set, a manual or automated single-use valve would be suitable. See our Single Use valve from Equilibar.

How to Size and Select a PRV or BPRV for a Bag Inflation Application

Determining the flow rate required for the PRV and BPRV is a relatively straightforward calculation. Most bag manufacturers recommend the maximum liquid fill for a particular bag, so the available headspace for gas can be easily calculated using the following equation:

Total Bag Volume – Max Liquid Fill Volume = Bag Headspace Volume

- Example: If the total bag volume is 500 L and the maximum recommended liquid fill is 80%, then the headspace volume for gas is 100 L (500L – (80% of 500)= 100L)

The flow rate is then easily calculated using this equation:

Bag Headspace Volume / Time Required to Inflate = Flow rate

- Example: Since the headspace volume is 100 L, if you wish to fill the bag at max inflation pressure in 2 minutes, then the flow rate is 50 L/min (100L / 2 min = 50 L/min)

To size and select the pressure reducing valve, and back pressure regulator you need three pieces of information.

- Flow Rate

- P1, the clean air or gas pressure coming into the regulator inlet

- P2, the

Sizing Criteria for Selecting a PRV

- Flow rate: Continuing with the example above, the bag inflation gas flow rate is 50L/min.

- P1: P1 (PRV inlet pressure) is the clean air or gas distribution pressure upstream of the PRV, typically between 80 psi and 120 psi.

P2: P2 (PRV outlet pressure) is the PRV setpoint. Since our example is a smaller bag, the maximum bag operating pressure is 0.5 psig; the PRV inflation pressure setpoint must be below that. For this example, we will use a setpoint 0.3 psig.

Sizing Criteria for Selecting a BPRV

- Flow rate: To maintain bag pressure, the BPRV vent valve flow rate will be the same as the bag inflation gas flow rate established for the PRV: 50L/min.

- P1: The P1 (BPRV inlet pressure) is the valve setpoint pressure, the pressure at which it will open to ensure that the bag never over inflates and never reaches the maximum operating pressure of 0.5 psig. The setpoint must be set above the PRV setpoint to ensure there is a differential pressure between the two to maintain proper flow. Bottom line:

- BPRV setpoint must be below the maximum operating pressure for the bag

- BPRV setpoint must also be above the PRV setpoint

For this example, we will use a setpoint pressure of 0.4 psig.

- P2: The P2 pressure is the vent line pressure downstream of the BPRV. Most vent lines (if designed correctly) will vent to atmospheric pressure, so 0 psig.

Final Note: The numbers used in this example have been chosen just to show how the process works. The setpoints for both valves should be determined and set during commissioning following the design engineer’s guidance.

Mechanics of a Single Use Bag Filling System

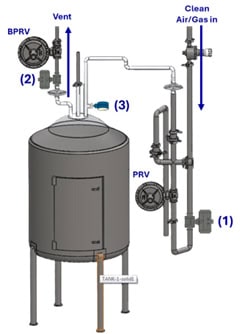

There are two primary mechanical systems involved with SU bag inflation; the gas supply (1), and the gas vent system (2).

- The clean air/gas supply system has two valves at the point of use: a Ball Valve (BV), and a Pressure Reducing Valve (PRV). The ball valve is used for primary air/gas shutoff and can be configured for manual operation or automated with an actuator. The PRV is used to manually set and regulate the incoming gas inflation pressure.

- The air/gas vent system requires a Ball Valve (BV), and Back Pressure Regulating Valve (BPRV). The ball valve is used for vent line shutoff (either manual, or automated). The BPRV is used to set and regulate the vent pressure, and is either manually controlled, or automated on air-loaded versions that include an I/P.

Single Use Bag Inflation System Operating Procedure

Once the bag and all tubing are connected and verified, and the PRV, BPRV and control system are installed, commissioned, and qualified, the system operation can begin.

Operating Procedure for Single Use Bag Inflation System

For Manual or Automated bag inflation systems

- Open the Gas Vent Pressure System (2), Ball Valve.

- Open the Clean Air/Gas Supply System (1), Ball Valve.

- Monitor the bag pressure gauge or pressure indicating transmitter (3) to ensure bag pressure is within the PRV and BPRV set points. If pressure is above set points, immediately close Air/Gas Supply Ball Valve (1). Investigate and adjust.

- When the inflation pressure stabilizes at the system’s inflation pressure setpoint, close both system ball valves (1) and (2)

- Monitor single-use bag pressure for pressure decay for a minimum of 60 seconds.

- If the pressure holds (no pressure decay), open the Gas Vent Pressure System Ball Valve (2) to relieve bag pressure.

- After a successful test, the single-Use liquid filling can begin. As the bag fills with liquid, all remaining air or gas in the bag will be displaced through the BPRV into the Vent Line.

Note: It’s important to follow the design engineer’s guidance during this procedure. It may differ from these instructions.