Sanitary Safety Relief Valves: Lifting Options & Lift Indicators

Ensuring Testability and Compliance in Hygienic Processing Applications

Sanitary Safety Relief Valves (SRVs) require specialized lifting mechanisms and indicators to meet the stringent requirements of hygienic processing industries including food, beverage, pharmaceutical, and biotechnology applications. These features enable valve testing without valve removal while ensuring compliance with ASME standards for high-temperature and steam applications.

Available Lifting Options

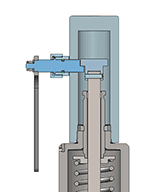

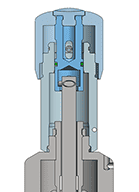

- Manual Lifting Knob (81/81V/83/83X Series)

– Allows 70% valve opening for cleaning without removal from process

– Maintains set pressure integrity during operation

– Features visual “Closed” indicator on bonnet when fully adjusted

– Ideal for applications requiring frequent manual inspection

2. Gas Tight Lifting Lever (88 Series)

– Provides 70% opening capacity for manual testing

– Enables cleaning without process interruption

– Maintains set pressure accuracy

– Suitable for applications requiring gas-tight seals

3. Gas Tight Lifting Knob for Manual Applications

– Manually lift the valve to 70% open

– Easily open the valve for cleaning without removing the valve from process

– Does not affect set pressure

4. Pneumatic Lift (All Series)

– Enables remote valve operation for automated CIP/SIP cycles

– Eliminates direct contact in sterile environments

– Reduces operator error through automation

– Required lift pressure varies by model and set pressure

– Essential for clean room and limited-access installations

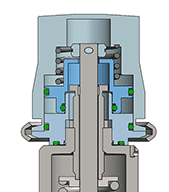

Key Hygienic Design Features

– Smooth, crevice-free surfaces prevent bacterial harboring

– 316L stainless steel construction allows use of aggressive cleaning agents

– Electropolished finish ensures cleanability

– Minimal dead legs in design eliminate non-turbulent contamination points

– CIP/SIP compatible materials and construction

– Remote monitoring capability reduces contamination risk

ASME Compliance

All Safety Relief valves must include lifting devices for:

– Steam applications at any temperature

– Air or water and liquid media applications exceeding 140°F

Process applications requiring sanitization fluid passage

When selecting lifting options and indicators for sanitary SRV’s, consider:

- Process temperature and ASME requirements

- Cleaning frequency and CIP/SIP protocols

- Access limitations in clean rooms or sterile areas

- Automation requirements for validation procedures

- Remote monitoring needs for critical processes

How Can We Help You With Your Sanitary Processes?

Contact us to learn more about how an SSRV can protect your sanitary process

Sanitary Safety Relief Valves

Sanitary Safety Relief Valves