Pressure Control in Clean Gas Distribution Lines for Cell Culture Production

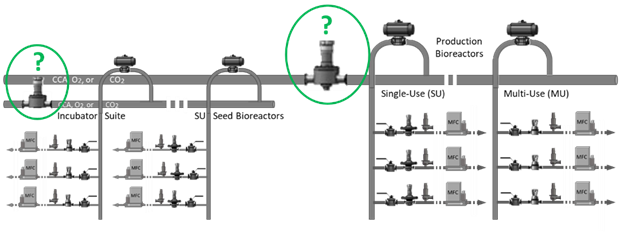

Application: Upstream – Cell Culture – Incubators, Seed Bioreactors

Media: Clean Air and Gas

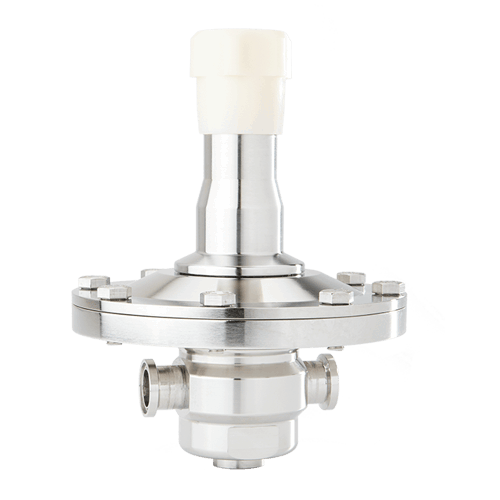

Valve Requirement: Pressure Reducing Valves

Pressure Control in Clean Gas Distribution Lines for Cell Culture Production

Precise clean gas pressure control is essential for reliable cell culture production in biopharmaceutical manufacturing. From incubators and seed bioreactors to large-scale production bioreactors, stable gas pressure directly impacts cell viability, gas transfer efficiency, and process repeatability.

This application note explains best practices for pressure reducing valve (PRV) placement in clean gas distribution systems and answers a common engineering question:

Is an upstream pressure reducing valve required ahead of the point-of-use PRV in biopharma gas distribution lines?

Clean Gas Pressure Control at the Point of Use

In biopharma facilities, point-of-use pressure reducing valves are commonly installed to regulate clean dry air (CDA) and process gases supplied to:

- Cell culture incubators

- Seed and production bioreactors

- Gas overlay and sparging systems

- Single-use bioprocess equipment

In most applications, an additional upstream PRV is not required when the point-of-use PRV is properly sized and rated for the available distribution pressure.

Steriflow Valve clean gas PRVs designed for biopharmaceutical service can safely handle inlet pressures up to 150 psi (15 bar) or higher, which exceeds typical clean gas distribution pressures.

Typical Clean Gas Distribution Pressures in Biopharma Manufacturing

Understanding standard gas supply pressures helps avoid unnecessary pressure regulation:

- Clean Dry Air (CDA) and Instrument Air

Typically distributed at 80–120 psi (5.5–8.3 bar) - Clean Compressed Process Gases (O₂, CO₂, N₂)

Often supplied at higher pressure but reduced for facility distribution - Bottled Medical-Grade Gases

Supplied at 800–3000 psig (53–200 bar) and reduced at the source - Cryogenic Liquid Gases

Vaporized and pressure-reduced in stages before facility distribution

As long as the gas distribution pressure does not exceed the PRV’s maximum inlet pressure, additional upstream regulators provide no process benefit.

Why Higher Inlet Pressure Improves PRV Performance

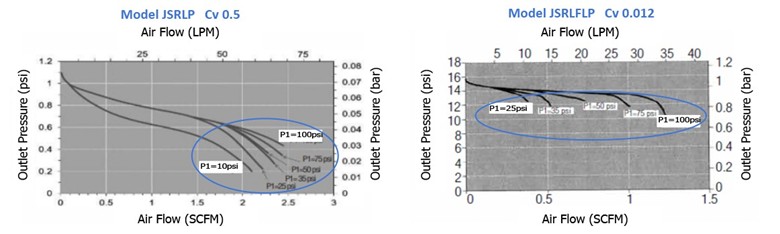

From a process control standpoint, higher inlet pressure (P1) improves pressure reducing valve performance.

Steriflow Valve clean gas PRVs operate most effectively at higher differential pressure (ΔP), resulting in:

- Improved flow capacity

- Reduced pressure droop

- More stable outlet pressure (P2)

- Better control under varying flow demand

Performance curves for Steriflow’s JSRLP and JSRLFLP Series clean gas PRVs demonstrate flatter outlet pressure profiles at 100 psi inlet pressure compared to lower inlet pressures—critical for maintaining stable bioprocess conditions.

When Is an Upstream Pressure Reducing Valve Required?

An upstream PRV should only be installed when:

- Gas distribution pressure exceeds the point-of-use PRV’s maximum inlet rating

In these cases:

- Install a primary PRV upstream

- Maintain the highest allowable downstream pressure to preserve point-of-use PRV performance

Maximum Inlet Pressure Exceptions for J-Series PRVs

- JSRLF (Low Flow PRV): up to 350 psi (24.1 bar)

- JSRH (High Flow PRV): up to 230 psi (15.8 bar)

Engineering Takeaway

- Fewer regulators mean simpler validation and lower risk

- Higher inlet pressure delivers better PRV control performance

- Proper PRV selection eliminates unnecessary hardware

- Designed-in stability supports robust cell culture processes

Bottom line:

If your clean gas distribution pressure is within the PRV’s inlet rating, don’t over-regulate. Let the point-of-use PRV do what it was designed to do—deliver stable, precise pressure control where it matters most.

Explore Clean Gas PRV Solutions

View the full range of Steriflow J-Series clean gas PRVs, including flow curves and performance data.

To access performance charts:

- Select a PRV model

- Navigate to Documentation → Series Data Sheet

- Download the data sheet for detailed flow performance information

JSRLP Series

JSRLP Series  JSRLFLP Series

JSRLFLP Series