Minimizing Flow Pulsations in Chromatography Skids

Advancing Pulsation Control with Active Dampening Technology

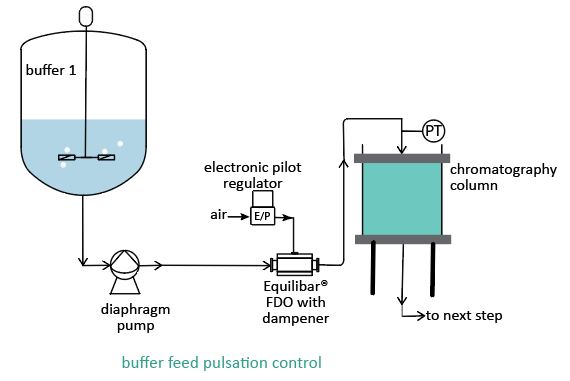

In biopharmaceutical processing, chromatography skids must manage a wide variety of fluids across multiple process steps while ensuring precise pressure and flow control. The delicate resins used in chromatography require stable conditions to prevent inefficiencies and maintain process integrity.

Key Challenges in Chromatography System Design

- Precise Flow Rate Control – Delivering consistent flow across a broad range, including very low flow rates.

- Eliminating Pulsations – Diaphragm pumps often introduce pulsations that can damage resins or create channeling, reducing process efficiency.

- Maintaining Consistent Back Pressure – Preventing bubble formation that can disrupt downstream operations.

How Steriflow/Equilibar Back Pressure Regulators Enhance Pulsation Dampening

Upstream Pulsation Dampening

Steriflow/Equilibar sanitary back pressure regulators (BPRs) naturally dampen upstream pulsations by stabilizing pressure fluctuations. The flexible diaphragm design adjusts instantaneously to slugs of fluid, keeping upstream pressure steady.

Downstream Pulsation Control

For downstream pulsation dampening, Steriflow/Equilibar BPRs include passive dampening inserts that help stabilize pressure fluctuations downstream of the regulator.

Introducing Active Pulsation Dampening Technology

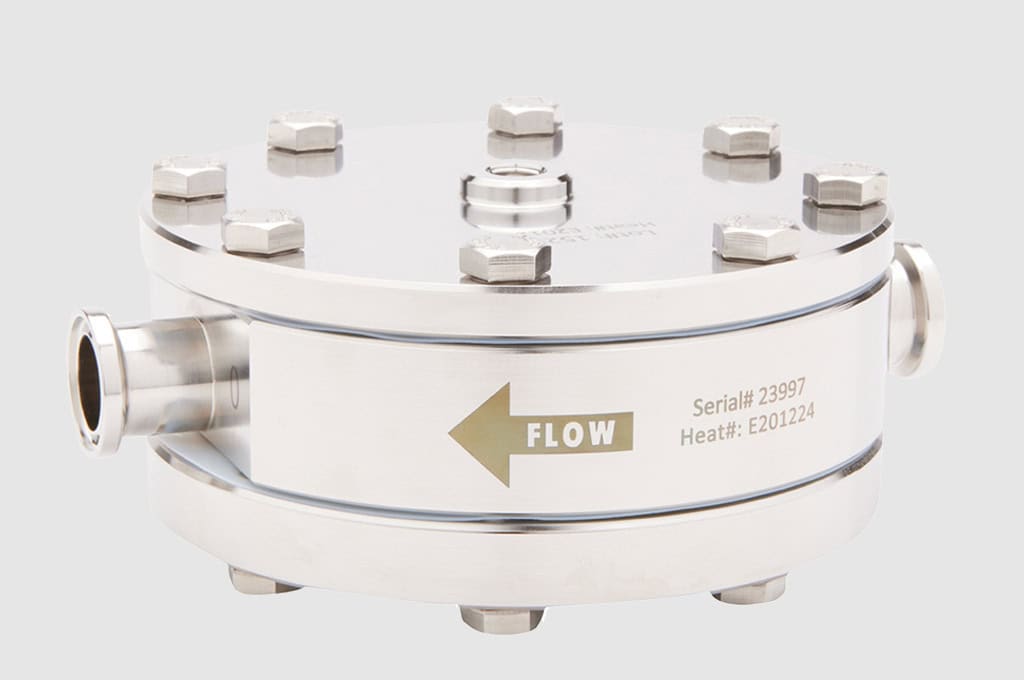

For processes with extreme downstream pulsations, Equilibar has developed an active dampening version of its FDO sanitary BPR. This enhanced design features a redesigned bottom cap to further reduce pressure fluctuations caused by pumps or other process equipment.

This beta-stage innovation offers:

- Instantaneous pressure stabilization across a wide range of flow rates.

- Enhanced control for chromatography skids where standard dampening methods fall short.

- Optimized performance for sensitive biopharma processes with tight pressure tolerances.

Case Study: Active Dampening in Biopharmaceutical Manufacturing

A biopharmaceutical purification platform designer integrated a Steriflow/Equilibar FDO BPR into a buffer and Water-For-Injection (WFI) delivery system. The system used a diaphragm pump to feed chromatography columns and filtration processes, with a standard Steriflow/Equilibar BPR installed downstream.

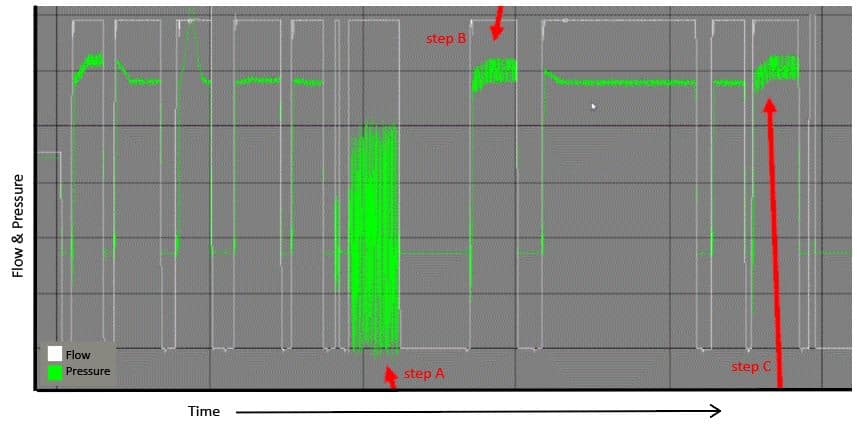

During testing, pressure pulsations were observed downstream of the BPR, raising concerns about potential chromatography disruptions and alarm-triggering pressure spikes.

The Solution: Steriflow/Equilibar BPR with Active Pulsation Dampening

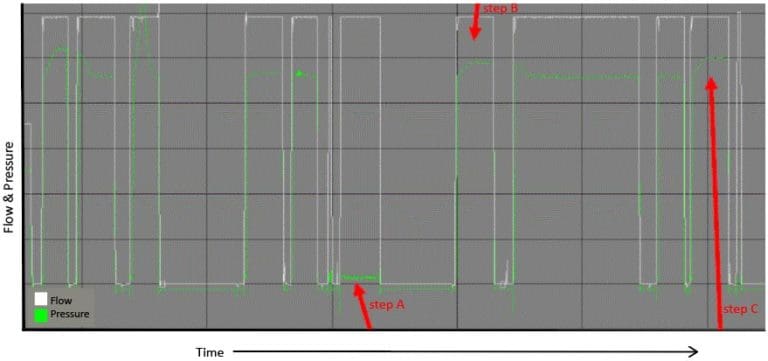

By replacing the standard BPR with the active dampening version, the process saw:

- A 99% reduction in pressure pulsations

- Greater stability in chromatography steps

- Improved process reliability and minimized risk of disruptions

Figure Comparisons

Figure 1: Pressure readings with a standard BPR – showing fluctuations in chromatography steps.

Figure 2: Pressure readings with the Steriflow/Equilibar active dampening BPR – demonstrating a dramatic reduction in pulsations.

Conclusion

Steriflow/Equilibar sanitary BPRs are engineered to provide unmatched pressure stability in biopharmaceutical processes. While passive dampening is standard in all Equilibar BPRs, the active dampening technology offers a breakthrough solution for chromatography skids requiring extreme pulsation control.

How Can We Help You With Your Sanitary Processes?

Learn more about how our Back Pressure Regulators can protect your sanitary process.

FDO Series

FDO Series