J-Series Clean Air and Gas Regulators: Self-Relieving Regulators explained

What is a Self-Relieving regulator? What function does the Self-Relieving option provide? Why would you choose that option? Let’s take a look and find out.

What is a Self-Relieving regulator? What function does the Self-Relieving option provide? Why would you choose that option? Let’s take a look and find out.

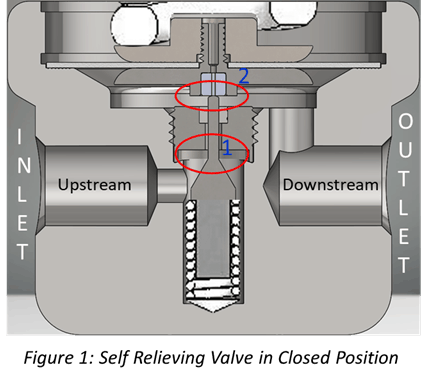

Figure 1 illustrates the typical physical characteristics of a PRV with the Self-relieving option. That’s the option that’s available on Steriflow’s Point of Use Gas Regulators. This particular drawing shows the cutaway view of that option in our JSRLF model, but the JSRLFLP, JSR and JSRLP all function in a similar manner.

Figure 1 also illustrates all gas regulators (PRV’s) in the closed position. When a gas regulator is installed and operating, closure occurs when flow stops. The main valve plug seats against the valves Soft Seat main orifice preventing upstream gas from leaking through (1).

Gas regulators with the Self-Relieving option have an additional feature. The top of the Stem (above the conical plug) rests up against a special PTFE Insert with an orifice (2) that is embedded in the Lower Diaphragm Plate. That PTFE orifice is the entry point of a passageway to the inside of the spring housing. The spring housing is exposed to atmospheric pressure. During normal closed conditions (when downstream pressure ≤ the regulators set point), and during flowing conditions, that orifice is sealed by the top of the stem (2).

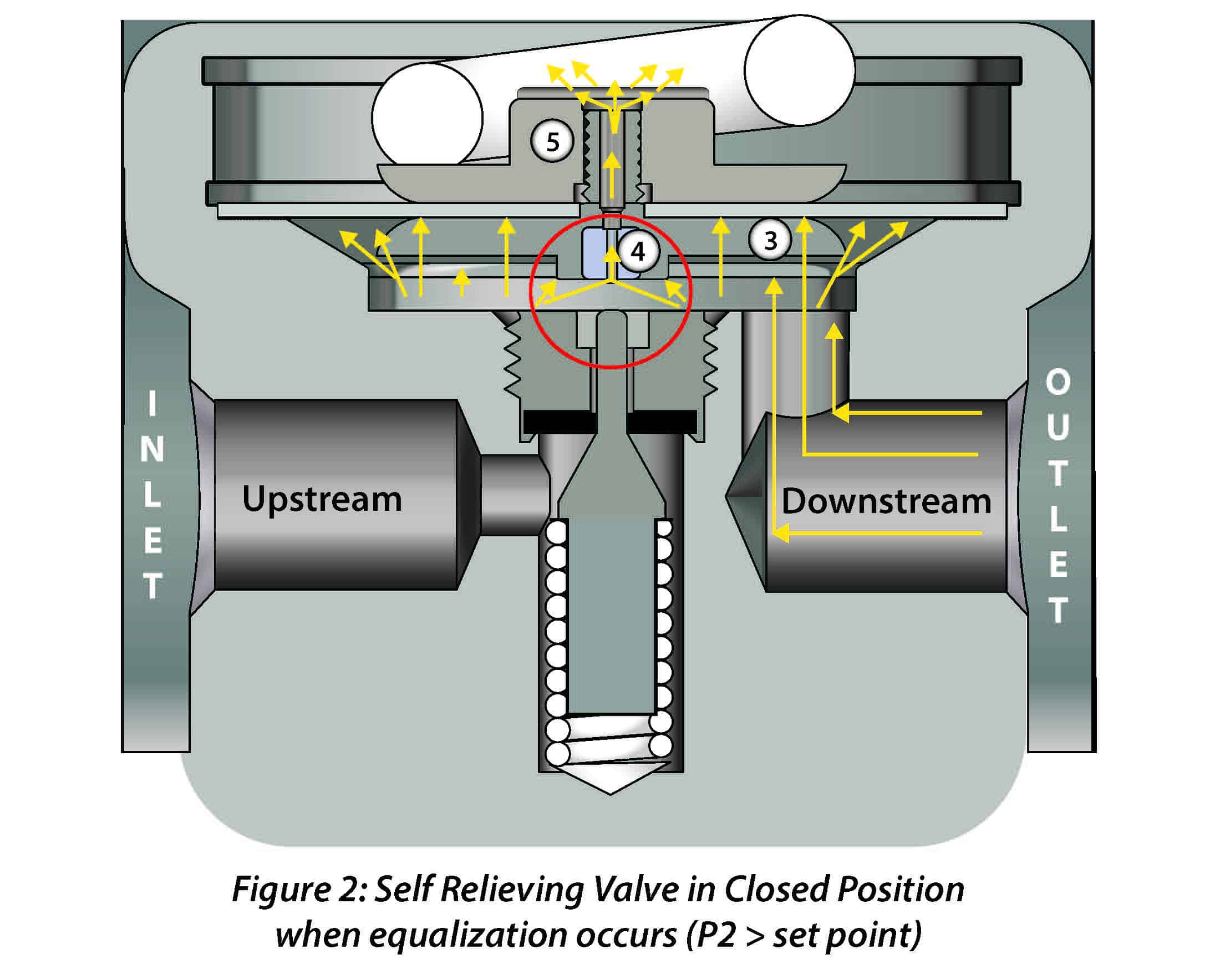

After closing, if the downstream pressure increases for any reason (equalization leakage for example) to a point where it is higher than the set point (P2 > set point), the excess pressure (3) will overcome the set point main spring force and push the diaphragm assembly off the top of the Upper Stem exposing the orifice in the PTFE Insert (4). The excess downstream pressure will vent through the PTFE orifice, through the passage in the diaphragm assembly (5) and into the spring housing. Once the excess pressure is vented, the diaphragm assembly will return to its normal resting position on top of the stem, sealing the orifice in the PTFE insert See Figure 1, (2).

I want to mention a few other points before we wrap up this discussion:

- If using the regulator to fill the top of a closed vessel (vessel with vent valve closed) to a specific pressure, flow will stop and the PRV will close when the pressure in the vessel reaches the set pressure. In industry parlance, this is called dead heading. In this state, even though the soft seated regulator’s shut-off class is ANSI/FCI Class VI, equalization will occur over time as described above. One way to eliminate that is to specify a regulator with a self-relieving option.

- Self-relieving regulators will also reduce what the valve industry calls “Lock-up”. Lock up is pressure set point creep when flow goes to zero. Creep is the opposite of droop. When flow through a gas PRV approaches zero, the outlet pressure will rise to exceed the set point. In other words, the outlet pressure tries to equalize to inlet pressure before the main plug seats. This is particularly true with gas PRV’s because of their relatively small diaphragms.

Lock-up, and pressure equalization over time, can be problematic, especially if a safety relieve valve is installed down-steam of the pressure regulator in a closed system. - Another reason for specifying a self-relieving regulator is if you want instantaneous relief of pressure. As long as gas is flowing through the PRV, you can raise and lower the set point at will. However, when flow stops and the regulator closes (with the area downstream of the regulator pressurized at set point), you cannot lower the set point to relieve pressure, unless the valve has a self-relieving feature. A self-relieving regulator will relieve the downstream pressure (in the same manner described above) to the new set point as soon as it is adjusted. A regulator that does not have that feature cannot be adjusted to a lower pressure when the flow stops because the regulator has no provision to bleed off the excess pressure.

- Lastly, if the regulated media is clean compressed process air, most users will normally allow the self-relieved air to vent through a weep hole in the side of the spring housing into the surrounding atmosphere. For example, Clean dry air could be vented to atmosphere. Note: For certain hazardous gasses, you must vent the gas via tubing to a safe location to prevent gas build up in the area around the valve. If so, order the Captured Vent option. That option provides a weep hole with an integral 1/8” FNPT fitting on the spring housing. With that option, a tube fitting can be installed and tubing run to a safe disposal area.