How to prevent bubble formation in chromatography columns

Application: Downstream – Chromatography

Media: Mobile Phase Flows

Valve Requirement: Pressure Control – BPRV

How can I Reduce Bubble Formation in my Chrome Column?

Gas bubbles formed from air or solvents coming out of solution (off-gassing) can be problematic in chromatography systems—whether occurring within the column itself or upstream of the analyte detector.

Why Bubbles Are Problematic in Chromatography Columns

- Disrupted flow patterns through the stationary phase

- Inaccurate analyte concentration measurements

- Compromised detector readings from partially-filled tubes

- Reduced separation efficiency and product quality

The Solution

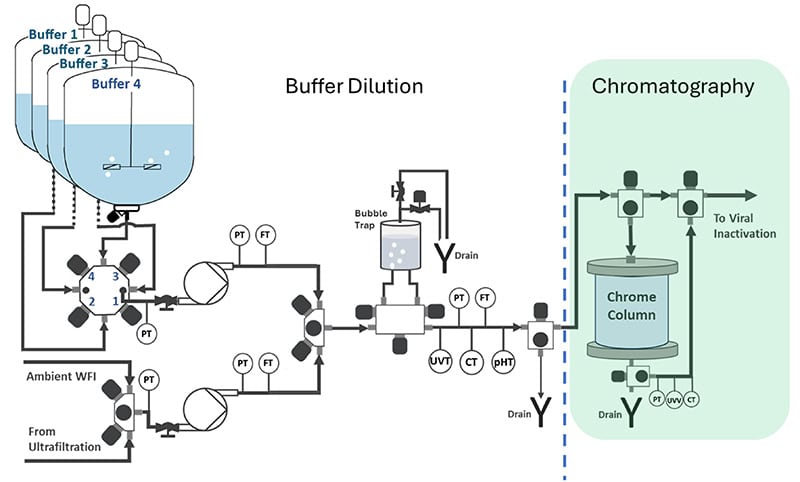

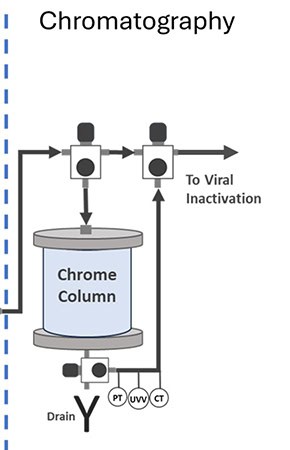

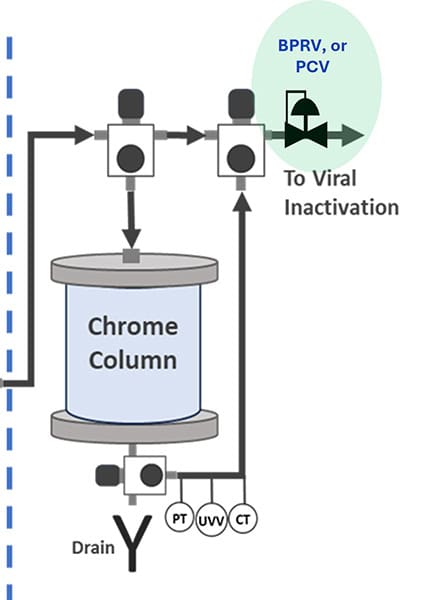

Using a back pressure regulator downstream of the chromatography column and detector lowers the differential pressure across the column, eliminating or minimizing bubble formation while ensuring a full tube at the detector for accurate measurements. Below is a typical flow schematic with instruments for a Buffer Dilution and HPLC Chromatography system.

Understanding HPLC Chromatography

Before addressing back pressure regulator placement, it’s helpful to review how High Performance Liquid Chromatography (HPLC) systems work.

HPLC Column Construction

The chromatography column consists of a stainless-steel alloy, glass, or single-use plastic cylindrical column packed with tiny wetted resin beads. This packed bed of resin beads is termed the Stationary Phase (also called the resin matrix).

Key Terminology in HPLC

- Stationary Phase

The packed bed of wetted resin beads inside the column, also called the resin matrix. - Mobile Phase

The fluids that flow through the column: Starting Buffer, Wash Buffer and Eluent - Analyte

The target biomolecule being separated and purified from the sample - Eluate

The released analytes combined with the eluent buffer exiting the column

The Chromatography Process

- Column Preparation

After column packing, a Starting Buffer (WFI diluted in a buffer/solvent mixture) rinses impurities from the stationary phase and preps the resin chemistry for sample loading. - Sample Loading

Ultrafiltrate diluted with WFI and buffer/solvent is pumped into the column, percolating through the stationary phase. The target analyte bonds to the resin beads while everything else drains. - Washing

A WFI-diluted Wash Buffer rinses everything from the column except the bonded analyte, removing remaining impurities. - Elution

An Eluent breaks the bond between the analyte and resin beads1. The released analytes (eluate) exit the column, pass over the detector, and proceed to the next purification step.

1Eluents change column chemistry by altering mobile phase properties (polarity, pH, salt concentration) to weaken biomolecule binding to the stationary phase—often through competition (e.g., salt ions competing for binding sites) or by changing the molecule’s charge to reduce affinity.

Why Off-Gassing Occurs

As mobile phase fluids pass from the higher-pressure column inlet to the lower pressure at the column outlet2, air and dissolved gases can come out of solution depending on the fluid’s vapor pressure, temperature, and system pressure.

Phase Change Mechanism

Phase change (vaporization) occurs when outlet pressure drops below the liquid’s vapor pressure at the current temperature. When this condition is met, the liquid begins to vaporize. In most cases, conditions are borderline—bubble formation may be minimal but still sufficient to affect detector measurements.

Partially Empty Tubes Affect Measurements

If process fluid moves out of the column to a lower elevation, a half-empty tube will directly impact instrumentation accuracy. Note that outlet pressure can be zero or even negative if there is no tubing restriction, or if a downstream pump is pulling the fluid column to the next purification step.

2Outlet pressure can be zero or even negative if there is no tubing restriction, or if a downstream pump is pulling the fluid column to the next purification step.

Solutions for Bubble Prevention

Reduced ID Tubing

Some column manufacturers install smaller ID tubing at the column outlet downstream of detector instrumentation

√ Simple, passive solution

√ No additional equipment

× Only effective within narrow flow/pressure range

× Ineffective outside specific conditions

Traditional BPRV or PCV

Spring-loaded back pressure regulators or linear pressure control valves provide automatic pressure adjustment

√ Broader operating range than tubing

√ Automatic adjustment

× Sizing must match conditions

× Limited turndown ratio

× Set point offset as flow changes

Recommended Solution: Equilibar FD Sanitary BPR

The Equilibar FD Series sanitary regulator is a dome-loaded back pressure regulating valve with exceptional turndown and accuracy for chromatography applications

√ 10,000:1 turndown ratio

√ Virtually no set point offset

√ Most compact BPRV available

√ Manual or PID control options

The Equilibar Advantage

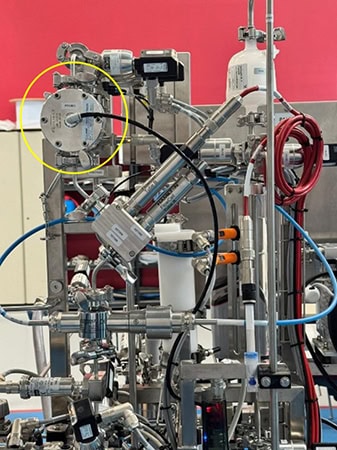

The Equilibar® FD sanitary dome-loaded back pressure regulator offers exceptional performance for chromatography column applications. Its unique dome-loaded diaphragm design provides unmatched accuracy across an extraordinarily wide flow range.

- 10,000:1 turndown with virtually no set point offset3 over the entire range

- Most compact BPRV on the market—minimal footprint on your skid

- Flexible control options: manual via self-relieving PRV or automated via I/P with PID loop

- Available in multi-use (FD) and single-use (SD) configurations

3 Set point offset describes the percentage change in set point pressure as flow increases or decreases from the flow rate at which the valve was originally set. Traditional valves exhibit significant offset; the Equilibar design virtually eliminates it.

Equilibar FDO4 back pressure regulator installed downstream of a chrome column. Primary purpose: maintain consistent differential pressure across the column to stabilize and prevent off-gassing of mobile phase fluids. Secondary benefit: ensure full pipe for inline sensors.

The Equilibar back pressure regulator technology is also available in a single use format, the Equilibar SD valve.

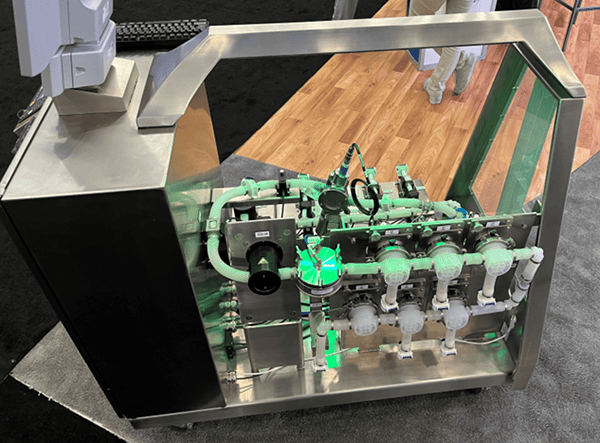

Equilibar SD Single-Use back pressure regulator on a Single-Use Chrome Column Inline Buffer Dilution (ILD) skid. Installed downstream of instrumentation to optimize pump head pressure and ensure full pipe.

Ready to Optimize Your Chromatography System?

Learn more about the Equilibar Model FD for multi-use applications or the Model SD for single-use systems. Our team can help you select the right solution for your specific requirements.

Equilibar FDO back pressure regulator

Equilibar FDO back pressure regulator