How Do I Size PRV Requirements For Cell Culture Processes?

Application: Upstream – Cell Culture – Incubators, Seed Bioreactors

Media: Clean Air and Gas

Valve Requirement: Pressure Reducing Valves

How do I determine how many Pressure Reducing Valves (PRV’s) will be needed to supply gas to incubators and seed bioreactors?

In cell culture processing, setting up a system with consistent clean gas supply for incubators and seed bioreactors is an important step. Minimum and maximum gas flow rates as well as pressure setpoints are critical parameters to know before choosing the clean air and gas regulators and the piping configuration for your system.

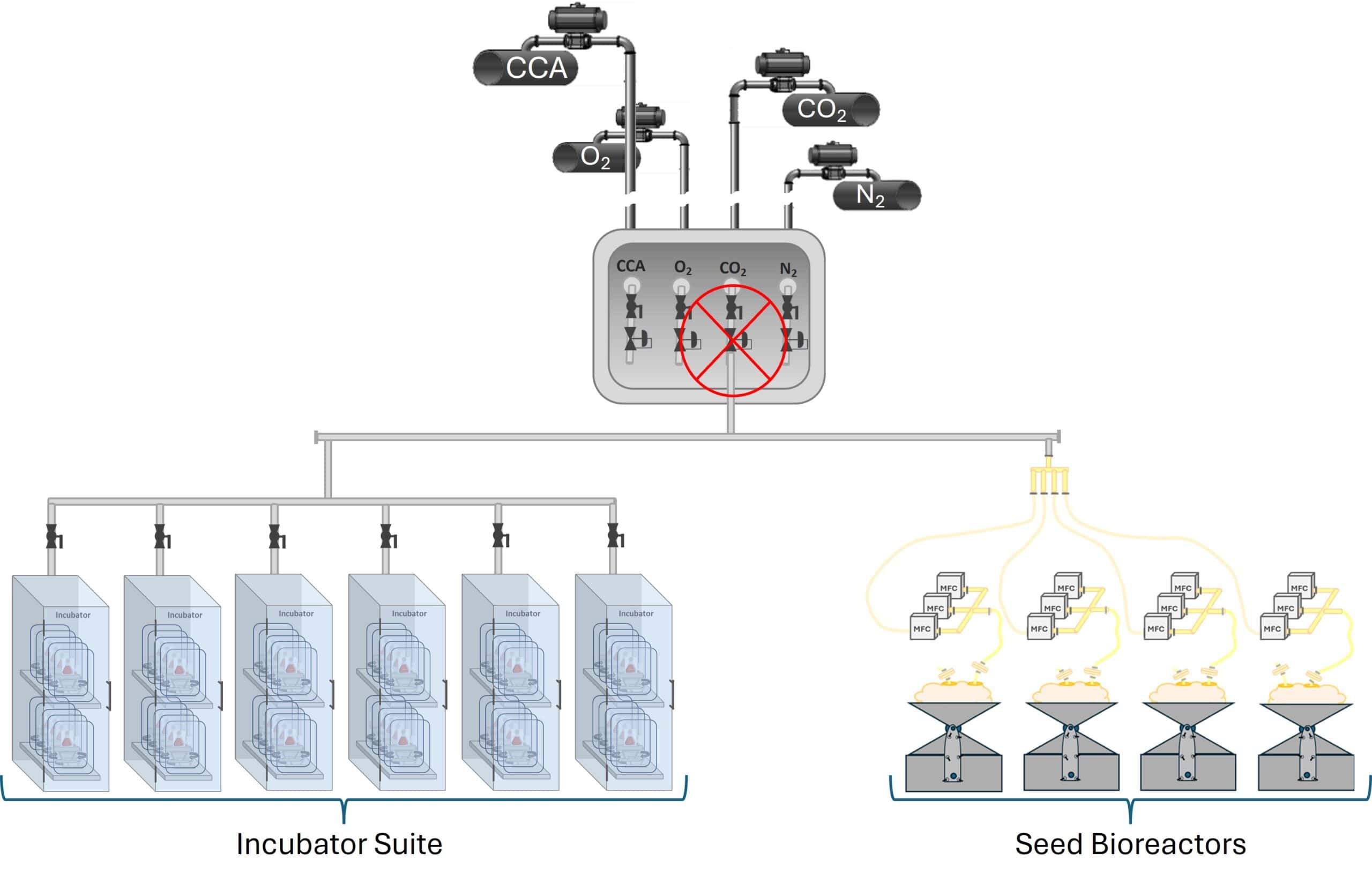

Take the system in the image below, for example. Here, PRVs are placed at the outlet of each of the seed gas lines which then go directly to both an incubator suite and seed bioreactor suite. Can you use just one PRV for each seed gas to supply the entire suite system?

It is highly unlikely that one PRV per gas feed can maintain pressure and handle the gas flow requirement for a suite of incubators and seed bioreactors even if the required pressure is the same. Minimum and maximum flow requirements for each Point-of-Use must be determined before that decision can be made.

A proper Clean Gas Feed System for a Cell Culture Suite will generally require additional PRV’s.

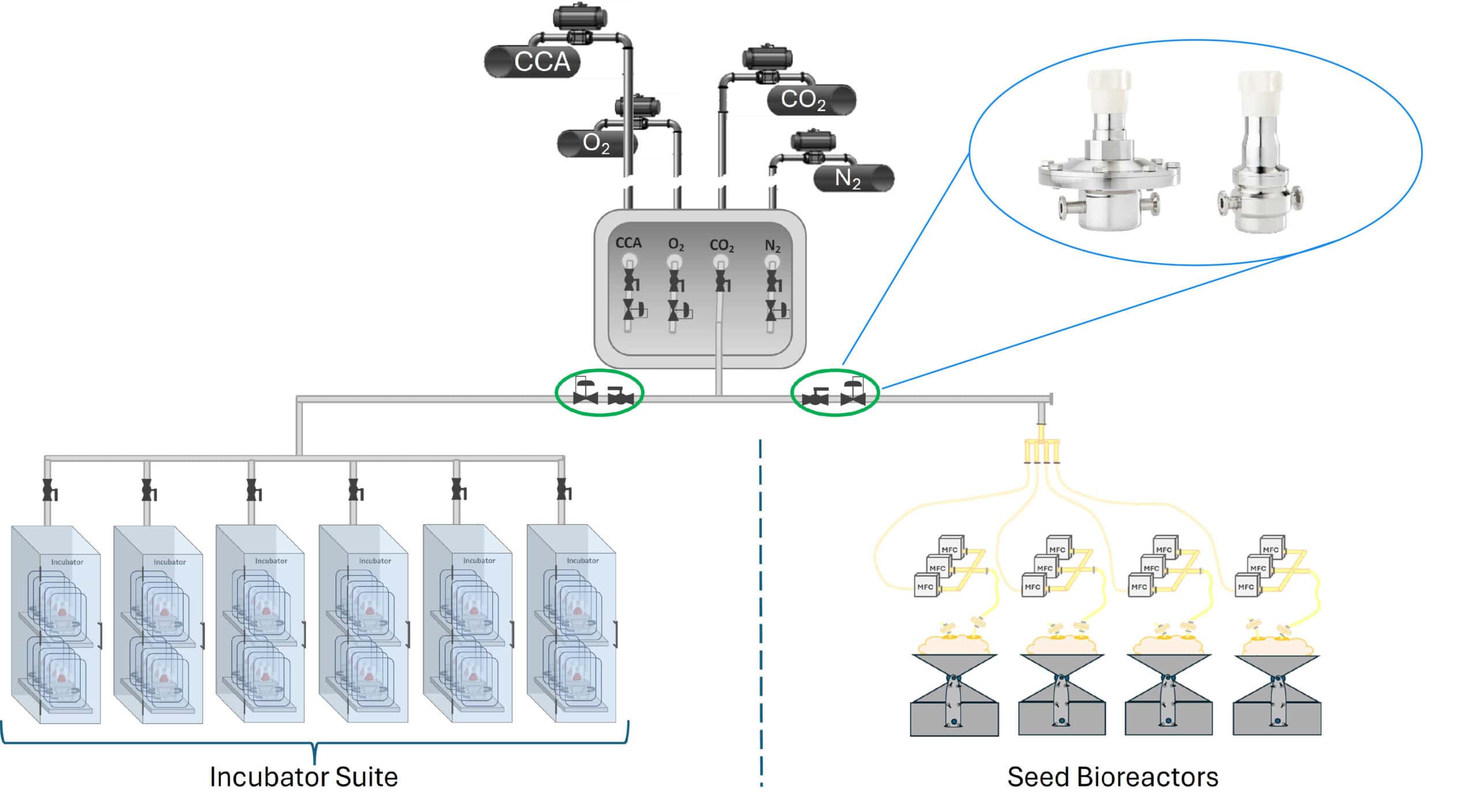

The image below shows an improved supply system design to handle the clean gas requirements of an entire cell culture suite system. As long as the minimum and maximum required gas flow is properly calculated and the Pressure Reducing Valves are chosen for that capacity range, this system design will be more robust than the earlier example.

To verify the design, check the minimum and maximum flow needed for each PRV against the PRV’s capability at the required inlet pressure and outlet pressure setpoints.

Calculating Minimum and Maximum Flow for Incubators:

- Minimum flow: The flow rate required for operating only one incubator with the door closed.

- Maximum flow: The flow rate required to operate all six incubators with their doors open

Calculating Minimum and Maximum Flow for Seed Bioreactors:

- Minimum flow: The flow rate required to supply only one operating bioreactor during batch.

- Maximum flow: The flow rate required to supply all four bioreactors during batch.

Comparing Flow Requirements with PRV Capabilities:

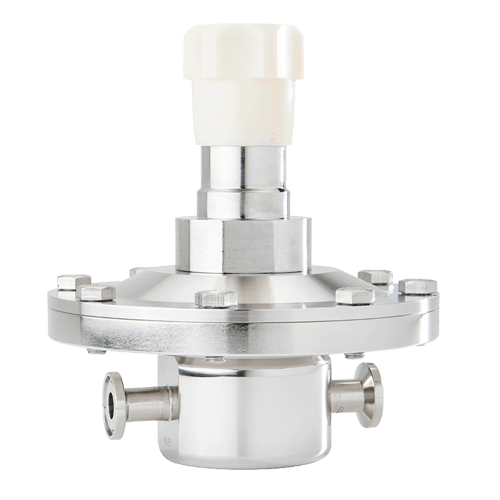

Steriflow Valve J-Series Clean Air and Gas Regulators are designed for this application. Follow this link to see J-Series offerings. Click on the product you want, then scroll down the page to Documentation > Series Data Sheet to find the flow performance charts for each pressure range. Compare the valve capability with the flow requirements. Contact us if you need help.

JSR Series

JSR Series  JSRLFLP Series

JSRLFLP Series