How Accurate Are Clean Gas PRVs in Cell Culture?

Application: Upstream – Cell Culture – Incubators, Bioreactors

Media: Clean Air and Gas

Valve Requirement: Pressure Control – PRV

How Accurate Are Clean Gas Pressure Reducing Valves in Cell Culture?

Clean gas pressure reducing valves (PRVs) regulate the downstream (outlet) pressure of clean air and gas lines used in cell culture processes. At a stable flow rate, PRVs are extremely accurate and maintain a steady setpoint ideal for incubators, seed reactors, and production bioreactors.

But cell culture processes may not operate at one flow rate. As flow changes, the outlet pressure can drift from the original setpoint, affecting the pressure consistency at the point of use.

Why PRV Accuracy Changes: Understanding Setpoint Offset

When flow changes from the rate at which the PRV was originally set, the outlet pressure shifts. This is known as setpoint offset, and it happens in two directions:

- Negative Offset (“Droop”)

As flow increases, the outlet pressure drops below the original setpoint. This negative offset is commonly called droop because the pressure curve “droops” downward as flow rises. - Positive Offset (“Build”)

When flow is reduced from the original outlet pressure setting, the outlet pressure builds above the setpoint. The pressure curve “builds” upward as flow lessens.

These behaviors are normal characteristics of clean gas regulators and can be predicted using PRV performance curves.

Does Setpoint Offset Affect Clean Gas Pressure in Cell Culture?

Short answer:

- For one PRV feeding a single bioreactor, it is usually not a problem.

- For one PRV feeding multiple points-of-use, offset can significantly affect your ability to control pressure and may require frequent readjustments over the batch.

One PRV for a Single Point-of-Use

When one clean gas PRV feeds a single bioreactor or incubator:

- Clean Air and O₂ flow is typically set at batch start and then left largely unchanged. Because the flow stays stable, the outlet pressure remains rock steady.

- CO₂ flow is sometimes adjusted during the batch to control broth pH, but once the new CO₂ flow is set, it often stays constant until the next small pH correction is needed.

- If the operator changes gas flow and notices a pressure shift, they simply readjust the PRV back to the original setpoint at the new flow rate. Once reset, the pressure remains stable at that operating condition.

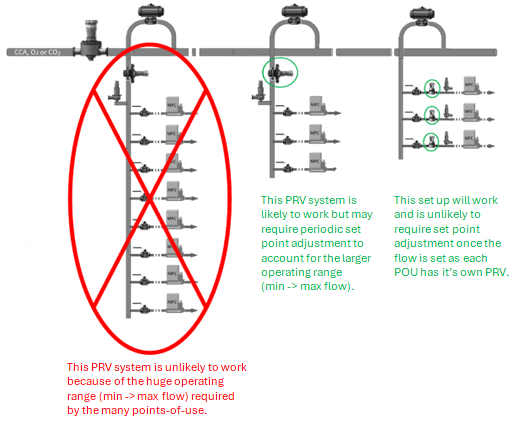

One PRV for Multiple Points-of-Use

For installations where one gas PRV is being used to control the pressure for multiple points-of-use (multiple bioreactors, seed bioreactors or incubators), offset becomes more significant.

In this case, the total flow through the PRV changes as different vessels start or stop consuming gas.

Consider:

- Minimum flow scenario: Only one point-of-use is active at minimum flow.

- Maximum flow scenario: All points-of-use are operating at maximum flow simultaneously.

- That is a very wide flow range for a single PRV to control with minimal offset. Operators may be forced to readjust the PRV multiple times during a batch to keep pressure within acceptable limits. This doesn’t mean a single PRV cannot be used—but offset must be carefully evaluated.

The illustration below demonstrates what different scenarios would not work, and those that will work.

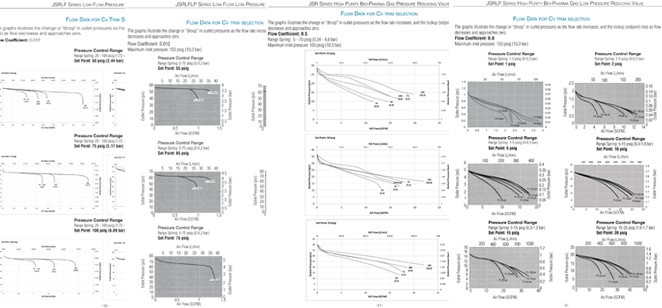

Using Performance Graphs to Evaluate PRV Accuracy

Regulator performance charts like those for JSRLF and JSRLFLP below show the relationship between inlet pressure, flow rate, outlet pressure and setpoint. By matching your process pressures and flows to the chart, you can find your valve’s expected performance. Steriflow provides many test charts per model, making it easy to find one close to your actual installation.

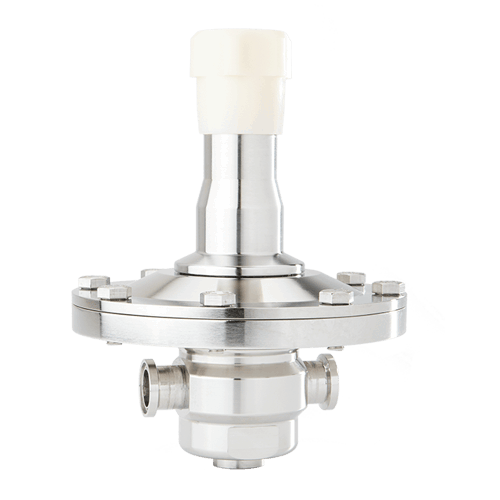

JSR Series

JSR Series  JSRLF Series

JSRLF Series  JSRLP Series

JSRLP Series  JSRLFLP Series

JSRLFLP Series