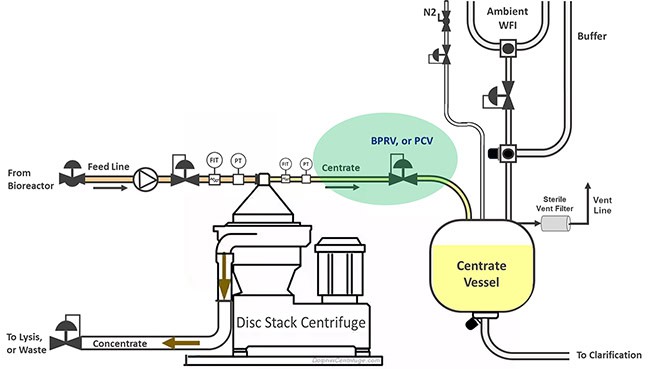

Centrifuge Centrate Back Pressure Control

Application: Upstream – Harvest – Centrifuge

Media: Centrate

Valve Requirement: BPRV or PCV

Why Accurate Back Pressure Control Matters

Accurate centrate line back pressure control is essential for optimizing separation efficiency in disc stack centrifuges. Without precise control, the centrifuge bowl level can vary and expose the pairing disc to air—significantly impacting your process outcomes.

Traditional Valve Solutions

What valves are typically used?

Traditional sanitary back pressure regulating valves (BPRVs) often lack the turndown required for centrifuge applications, and their accuracy is limited by setpoint offset (creep) as flow changes. For this reason, most past and current installations utilize a traditional sanitary pressure control valve (PCV).

PID-controlled PCVs offer better turndown and accuracy than traditional BPRVs. However, centrifuge centrate back pressure control remains a challenging application due to the inherent vibration from centrifuges operating at 10,000–40,000 rpm.

Maximizing Traditional PCV Performance

If you’re using a traditional sanitary pressure control valve, following these installation guidelines can significantly extend valve life and improve accuracy in demanding centrifuge environments.

- Vibration Dampeners

Install rubber mounts, flexible connections, or anti-vibration pads between the PCV and the mounting bracket to absorb mechanical vibration. - Secure the PCV Properly

Traditional linear control valves have a long movement arm that magnifies vibration

– Secure both the valve body and actuator to a strong pipe support, especially for horizontal mounting

– Check and tighten all bolts and connections on the PCV, pipe support and nearby piping regularly - Isolate from Centrifuge Vibration

This is critical. Where possible, install a sanitary Teflon-lined, flexible braided hose between the centrate line and the valve to dissipate severe vibration from high-speed centrifuge rotation

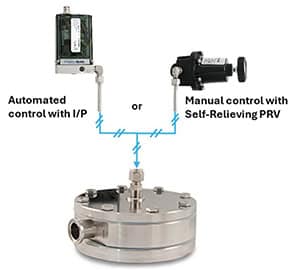

Advanced Solution: Equilibar Model FD

Model FD Sanitary Back Pressure Regulator

There is a sanitary back pressure regulator manufactured by Equilibar that is specifically designed for demanding applications like centrifuge centrate pressure control.

- Compact wafer-style body with only two moving parts (robust Jorlon™ diaphragms)

- Drastically reduced installation moment arm compared to traditional PCVs

- Less than 30% of the components found in traditional PCVs

- Pneumatically actuated via remote/direct I/P or self-relieving PRV

- Integral pulsation dampening feature for both inlet and outlet

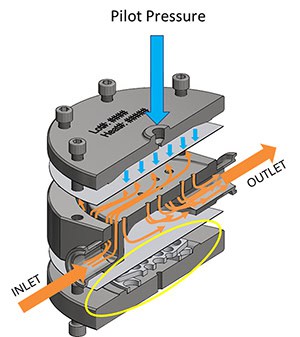

How the Equilibar FD Works

Simply load the Equilibar back pressure regulator with pilot pressure equal to the desired back pressure—the valve does the rest. Because the area above and below the upper diaphragm is identical, the air load pushing down is perfectly balanced against the inlet pressure.

- Pilot pressure forces the flexible diaphragm down onto a plate of orifices

- Rising inlet process pressure lifts the diaphragm to relieve excess pressure through outlet orifices

- Falling process pressure causes the diaphragm to move closer to orifices, restricting flow and rebuilding upstream pressure

- Extraordinarily accurate control over a very large turndown range (10,000:1)

Integral Pulsation Dampening

The Model FD includes built-in pulsation dampening that traditional valves cannot match. Pump fluid pulsations at the inlet are dissipated against the upper diaphragm and pilot pressure feed. Downstream pulsation is absorbed through the lower diaphragm, which sits on a silicone honeycomb passive dampening insert in the vented lower chamber.

Installation Recommendations

While the Model FD’s compact design significantly reduces vibration sensitivity, we still recommend:

- Support Brackets

Secure the valve body and I/P (or PRV) to support brackets, with optional vibration dampeners - Flexible Hose

Teflon-lined, flexible braided hose between the centrate line and valve is advised but not required - Flexible Pneumatic Tubing

Use a short section of flexible pneumatic tubing between the I/P (or PRVs) and the FD pilot pressure connection

Technology Comparison

This comparison illustrates the differences in turndown, accuracy, and reliability between valve technologies for centrifuge centrate back pressure control.

Ready to Optimize Your Centrifuge Operation?

Learn more about the Equilibar Model FD for multi-use and single-use centrifuge applications, or contact our team to discuss your specific requirements.