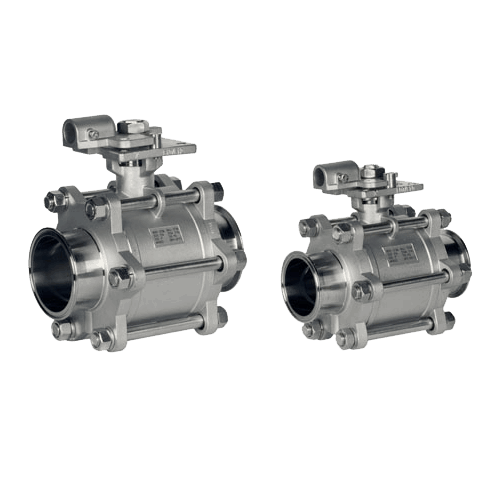

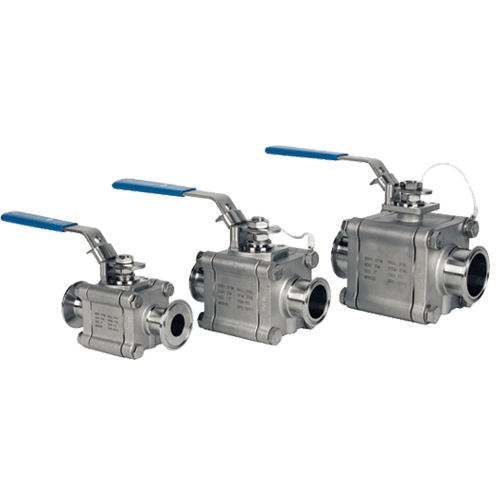

Sanitary Ball Valves

Three piece, full bore sanitary ball valves, low ferrite 316L, 1/2" - 4" (DN15 - DN100), TFM seats (cavity and non-cavity) and seals, for pharma clean steam, air and gas, acids and pneumatic conveyance of pharma powders.

Mark 9020 BPE Series ⟶

2-Way Sanitary Ball Valves

Mark 9020D DIN Series ⟶

2-Way Sanitary Ball Valves

Mark 9020S ISO Series ⟶

2-Way Sanitary Ball Valves

Your List

Email List

Get A Quote

How do the Sanitary Ball Valves Work?

A sanitary or hygienic ball valve uses a precision-machined spherical ball with a through-bore that rotates within the valve body to control fluid flow. This design provides reliable, quarter-turn on/off control ideal for hygienic processing systems.

Full-Bore Design Advantages

Steriflow sanitary ball valves feature a full-bore design where the valve opening matches the pipe diameter exactly. This design delivers:

- Unrestricted flow with minimal pressure loss

- Superior performance with viscous liquids and particle-laden fluids

- Enhanced cleanability for CIP (Clean-in-Place) operations

Key Applications of Hygienic Ball Valves

Steriflow sanitary ball valves excel in demanding applications, including:

- Clean-in-Place (CIP) and Sterilize-in-Place (SIP) operations

- Clean Compressed Air

- Clean utilities: clean steam, USP PW, CIP, acids and solvents

- Process and clean utility waste lines

Why Choose Steriflow Sanitary Ball Valves?

Simple 3-Piece Design

- Minimal moving parts reduce maintenance requirements

- Easy access for inspection and servicing

Premium Materials & Construction

- Durable TFM (modified PTFE) seats extend service life

- 316L stainless steel construction with superior corrosion resistance

- Nylon handle covers ensure safe manual operation at elevated temperatures

Our Product Range

Steriflow offers three sanitary stainless steel ball valve series includes ASME BPE, DIN, and ISO configurations to meet diverse industry requirements:

| Series | Standards | Applications | Key Features |

| Mark 9020 BPE Series | ASME BPE | Pharmaceutical, biotech, high-purity applications | Ultra-clean hygienic performance, bioprocessing equipment standards |

| Mark 9020D DIN Series | DIN Standards | European processing industries | Full compatibility with DIN piping and fittings |

| Mark 9020S ISO Series | ISO Standards | Global applications across all industries | Universal compatibility, versatile design |

Available Configurations:

- Multiple sizes from ½” to 4″ (and larger upon request)

- Various end connections: tri-clamp

- Custom specifications available

Industry Applications

- Dairy processing and packaging lines

- Beverage production and filling systems

- Food ingredient handling and mixing

Pharmaceutical & Biotechnology

- API manufacturing and purification

- Vaccine and biologic production

- Laboratory and pilot plant applications

Personal Care & Cosmetics

- Lotion and cream manufacturing

- Shampoo and conditioner production

- Fragrance and essential oil processing

Technical Specifications

- Size: 1/2″ – 4″ (DN15 – DN100)

- End Connections: ASME BPE, Tri-clamp or extended tube weld ends; DIN 11866-A or B (ISO) extended tube weld ends standard and in stock

- Max Pressure/Temperature: To 1000 psig (69 barg) @ 100ºF (38ºC); 500 psig (34,5 barg) @ 295º (146ºC)

- Seat & Seal Material: TFM 1600 non-cavity filler seats and all seals. FDA, USP Class VI and USP

- Wetted Material & Surface Finish: ASTM A351 CF3M with <3% or 1% ferrite SF1, 20 ra µin (0.5 Ra µm) mechanical polish standard SF4, 15 Ra µin (0,4 µm) electropolish optional

Ready to Optimize Your Process?

Contact our technical specialists today to discuss your specific application requirements. Our team will help you select the ideal Steriflow sanitary ball valve for maximum performance and reliability.