J-Series Clean Air and Gas Regulators: Point of Use Clean Gas Regulator Basics

How do standard POU regulators function? What are the basic components?

How do standard POU regulators function? What are the basic components?

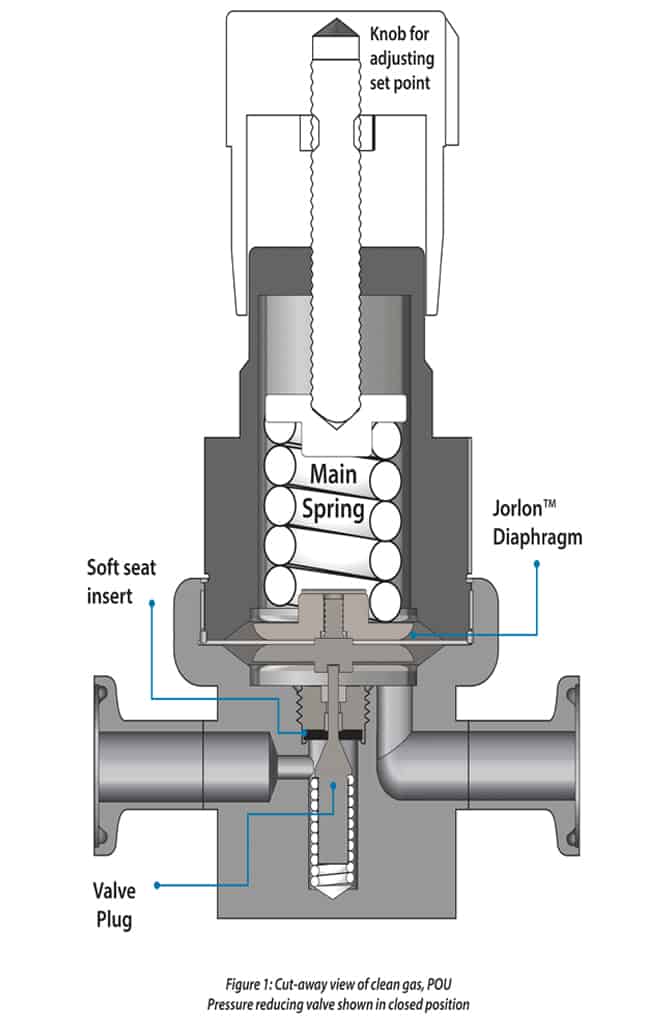

Figure 1 illustrates a standard off-the-shelf clean gas regulator: These regulators are usually constructed of, and certified to the following standards: 316L barstock material with a 20 Ra µin (0,5 Ra µm) Electropolished finish for the body and wetted trim (stem and plug). The diaphragm and soft seat are FDA and USP Class VI certified thermoplastics and elastomers.

The PRV in Figure 1 is shown in a closed position. However, if that regulator were actually sitting on a work bench at atmospheric pressure it would normally be open. That’s because the Main spring force (pushing down on the diaphragm) exceeds the opposing force from the small, non-adjustable return spring, and more significantly, the pressure on the underside of the diaphragm… the pressure from the outlet side of the of the valve. Since the stem and plug are affected by, and connected to the position of the diaphragm, the main spring ultimately pushes the stem and plug in a downward direction, away from the soft seat insert, opening the valve.

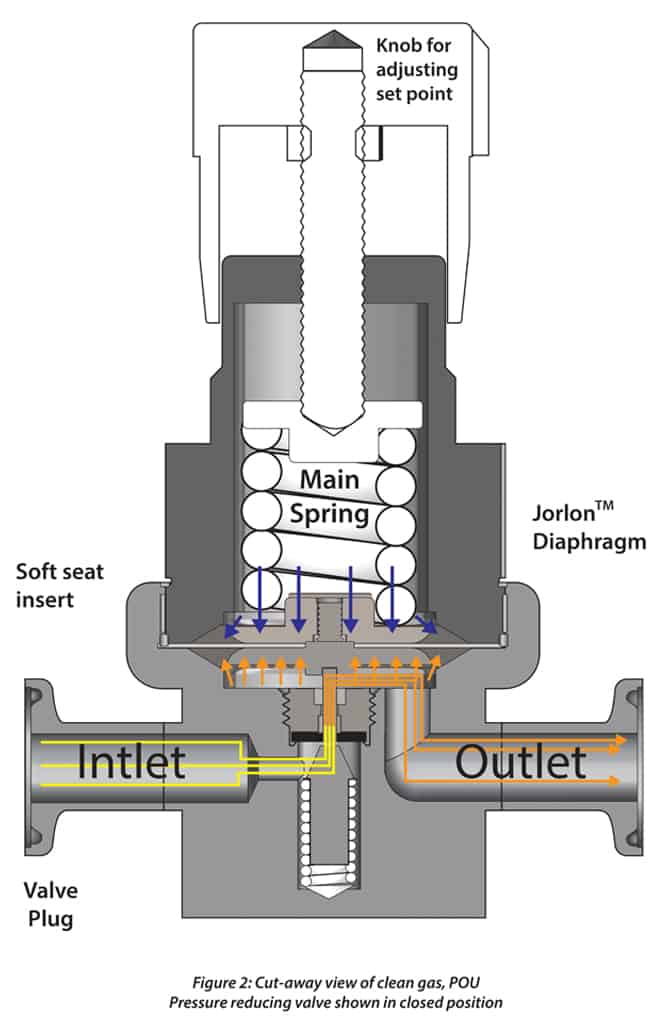

Installed and under operating conditions, the principals are the same but the action is a little different. Gas will flow through a PRV as long as the outlet pressure is lower than the main spring force – the set point. As the outlet pressure increases and rises to the valve’s set point, the diaphragm is pushed upward with the stem and plug following (in a closing direction), until the forces are in balance. When the forces are balanced, the force exerted by the main spring (the set point pressure) is equal to the force exerted by the outlet pressure. The diaphragm and plug will stay in that position as long as the flow rate stays the same.

If flow ultimately stops, for example, if someone closes a valve downstream of the regulator, the regulator will close but not before some of the upstream pressure leaks across the orifice. This is called Lock-up.

Also, even though most clean gas regulators have ANSI/FCI class VI shut off, ultimately when closed, there will be slight leakage – that depending upon downstream volume, will allow upstream pressure to ultimately equalize across the seat. If your installation requires a Safety Relief Valve (SRV) downstream of the regulator, it is important to know about this effect.

In the next Part of this series, we will discuss ways to alleviate, and prevent this build up in pressure.

Subscribe to Steriflow's Blog!

Be one of the first to watch new how-to videos, read published articles, and hear from experts about all things related to sanitary processing systems.