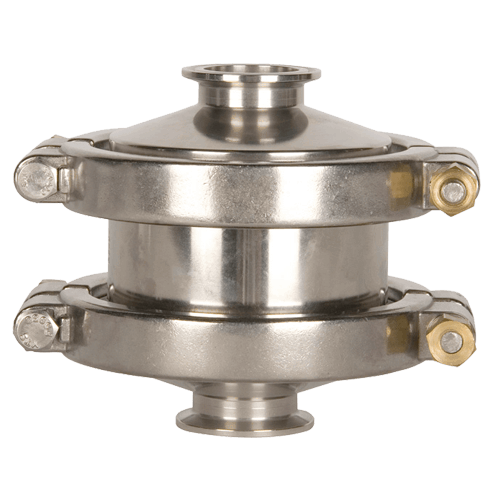

Mark 934 Series

High - ultra flow, <3°F (1.7°C) subcool operation

Three piece, bolted tri-clamp body, very high capacity, dual balanced port, thermostatic sanitary steam trap with integral bypass and vertical or horizontal inlet and/or outlet connections for pure steam SIP and clean utility drain applications in biopharmaceutical and aseptic food & beverage and consumer health & beauty industry applications.

- Up and downstream process vessel: large vessel, validated SIP drainage applications

- Up and downstream process vessels: use instead of SIP bypass loop on large vessel; validated SIP drainage from very large vessels

- Larger filter validated SIP drainage

- Filling machine or other larger volume validated SIP drainage

- Large autoclaves

- Significant CAPex savings: the MK934 with it’s integral bypass is designed to eliminate the need for an automated 3-way clean utility bypass valve at bottom of vessel

- Plant availability increase elimination of the bypass valve expedites heat-up and/or reduces pure steam waste as it disallows escape of pure steam before heat up to 85°C. All of the steam heats the vessel

- Low subcool operation reduces probability of temperature validation faults and resultant SIP delays

- For very large process vessels and equipment

- Self draining when installed with body vertical, regardless of whether inlet/outlet connections are vertical or horizontal

- Size: 1″, 1-1/2″, 2″ (DN25, DN40, DN50)

- Installation Connection Orientation: Vertical, Horizontal

- Connection Type: ASME, DIN, ISO Tri-Clamp and Tube Weld Ends

- Max. Allowable Pressure/Temperature: 145 psig (10 barg); 350°F (177°C)

- Maximum Operating Pressure: 50 psi (3,4 bar)

- Materials of Construction: Wetted body/plug material: ASTM SA479 316L (UNS 31603) is standard, EN 10272:2000 GR 1.4435 is optional. Body gaskets: various, FDA and USP Class VI

- Nominal Cv (Kv): 5.7 (4,93)

- Surface Finish: Internal: SF1, 20 Ra μin (0,5 μm) standard; SF5, 20 μin (0,5 Ra μm) electropolish or better optional

- Subcooling: Less than 3°F (1.7°C)

An Overview of Steam-In-Place

A comprehensive overview of SIP, existing components, piping design, and the new technology used to reduce common problem occurrences.

Steam Trap Comparison Chart

Understanding the differences among the full line of Steriflow steam traps

- CRN (Canadian Registration Number)

- PED Category 1 (Pressure Equipment Directive)

- SEP Declaration (Sound Engineering Practice)

- ATEX Certified

- EC Declaration of Conformity

- All products use FDA and USP Class VI approved soft goods and seals where possible. Consult each product data for details

Your List

Email List

Get A Quote

Related Products

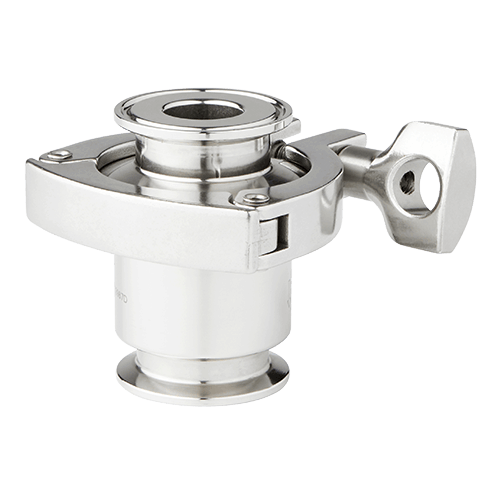

Mark 94 Series

High flow, <3°F (1.7C °C) subcool operation

Mark 93 Series

Medium to high flow, <3°F (1.7°C) subcool operation

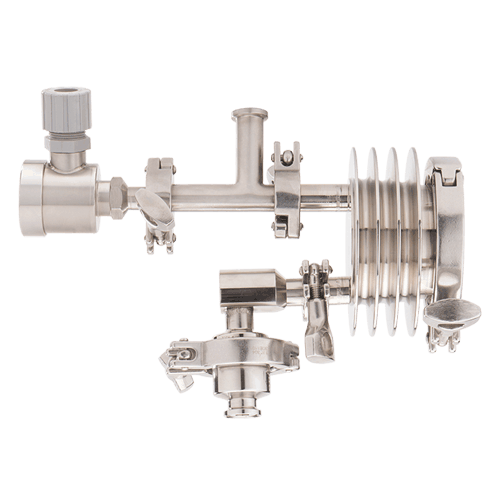

SSC Series

For compact, validated SIP sensor/steam trap drain installations

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.