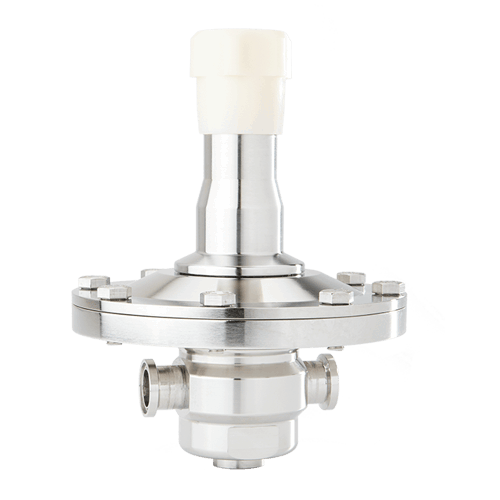

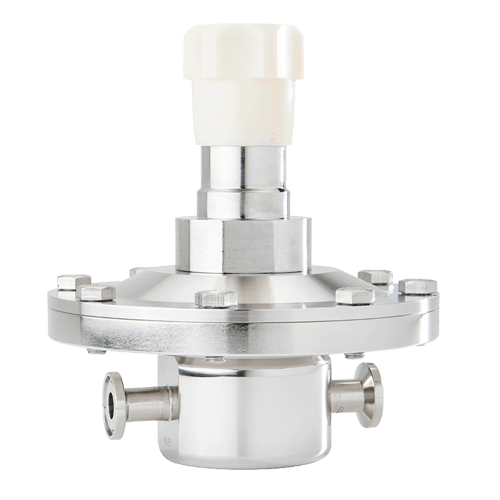

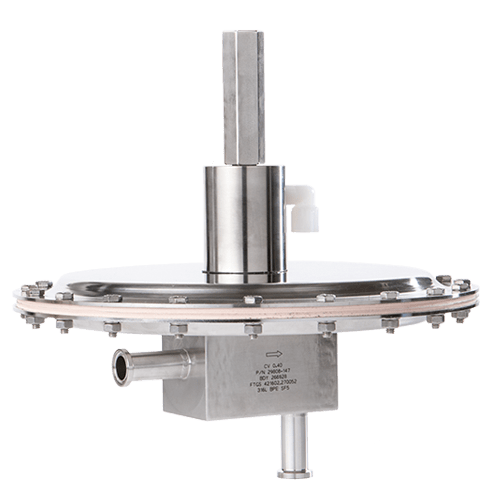

JSRLP Series

Manual or Air Augmented, Low to Medium Flow, Low Pressure, Jorlon Diaphragm

Inline style, manual or air loaded, pressure reducing valves for low to medium flow, low pressure clean compressed air and gas point of use applications in stainless steel and single use disposable vessels for the Biopharmaceutical, Pharmaceutical, Food & Beverage and Consumer Health & Beauty industries.

Small to medium small stainless steel or single use disposable bioreactor/fermenter, sparge, gas, purge/blanket/motive force gas regulation and bag integrity testing

Separation: purge/blanket/motive force gas regulation and bag integrity testing for process vessels

Purification: purge/blanket/motive force gas regulation and bag integrity testing for process vessels

Formulation: purge/blanket/motive force gas regulation and bag integrity testing for process vessels

Lyophilization: purge gas regulation

F & B Consumer H & B process purge/blanket/motive force gas regulation

- Stable outlet pressure setpoints to as low as 1 psi (69mB)

- Top entry design facilitates in-line cleaning and maintenance

- Barstock construction guarantees material integrity and quality surface finish

- Proprietary Jorlon diaphragm material provides exceptionally long life

- Low lock-up with EPDM seat

Note: These valves may be used on non-cavitating liquid or clean steam applications. However, they are not drainable. Steriflow Engineering must review application before acceptance.

- Size: 1/2″ & 3/4″ (DN15 & DN20)

- End Connections: ASME BPE, DIN and ISO Tri-Clamp, Weld-stud or NPT ends, VCR connections optional – contact factory

- Cv (Kv): 0.8 (0,7); 0.5 (0,43)

- Max. Inlet Pressure: 150 psi (10,5 bar)

- Setpoint Range: 1 – 50 psi (0,07 – 3,4 bar)

- Wetted Material: ASME SA479 316L (UNS 31603) is standard. EN 10272:2000 GR 1.4435, AL-6XN®, Hastelloy C-22 and others are optional

- Surface Finish: ASME BPE SF5, 20Ra (0,5µm) electropolish is standard; Non-EP is optional, as are other finishes

- Diaphragm Material: Jorlon FDA/USP Class VI

- Soft Seat Option: PTFE, PEEK, EPDM (all materials to FDA USP Class VI)

Jorlon Facts and Warranty

The majority of Steriflow valves come with the Jorlon diaphragm and, of course, a lifetime diaphragm warranty.

Jorlon Diaphragm InfoGraphic

Save money, extend preventive maintenance diaphragm change-out times, and realize the benefits of a valve that outlasts most normal systems.

PRV Gas Regulation Comparison Chart

Understanding the differences among pressure regulating blanketing valves

CRN (Canadian Registration Number)

SEP Declaration (Sound Engineering Practice)

ATEX Certified

All products use FDA and USP Class VI approved soft goods and seals where possible. Consult each product data for details

JSRLP Series

1/2″ JSRLP Series with Tri-Clamp Ends (20 Ra EP) and Port “A” Configuration

1/2″ JSRLP Series with ISO Tube Weld Ends (DN15) and Port “A” Configuration

1/2″ JSRLP Series with FNPT Ends (20 Ra EP) and Port “A” Configuration

1/2″ JSRLP Series with ISO Tri-Clamp Ends (DN15) and Port “A” Configuration

1/2″ JSRLP Series with Tube Weld Ends Ends (20 Ra EP) and Port “A” Configuration

3/4″ JSRLP Series with Tube Weld Ends Ends (20 Ra EP) and Port “A” Configuration

3/4″ JSRLP Series with Tri-Clamp Ends (20 Ra EP) and Port “A” Configuration

3/4″ JSRLP Series with FNPT Ends (20 Ra EP) and Port “A” Configuration

Your List

Email List

Get A Quote

Related Products

JSRLFLP Series

Manual or Air Augmented, Low Flow, Low Pressure, Jorlon Diaphragm

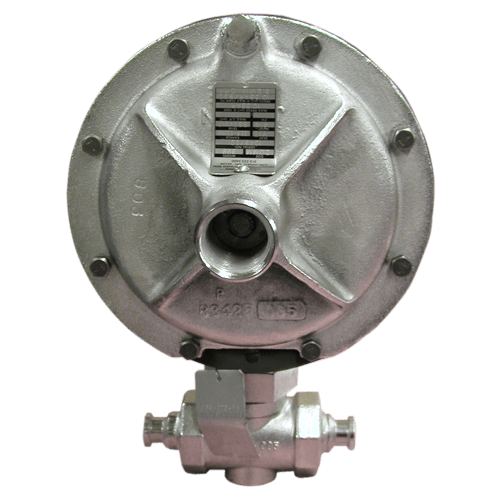

Mark 968 Series

Manual, Cast, Medium to High Flow, Very Low Pressure

Mark 908 X Series

Barstock Construction, Low Flow, Very Low Pressure

Accurate regulation down to 1/2" wc (1,25 mbar)

Low pressure blanketing (gas overlay) PRV for small stainless and SUD vessels

Quick Quote

Know what you need and want a quote quickly? We can help! Fill out this form and we will get back to you shortly.